Main Menu

Menu

Celebrating 65 Years

Better powder handling

since 1958

Our Story

For better powder handling since 1958

If you’ve ever eaten a cake, enjoyed a cola, or coated a wall with paint, chances are Floveyor played a part in getting those products into your hands. Floveyor has been helping small manufacturers and world-renowned brands build efficiency and safety into their production lines since 1958.

Founder Robert Walker’s curiosity and passion for engineering drove the creation of an aero-mechanical prototype for moving peanuts. He patented the aero-mechanical method of conveying (AMC).

Today, our proprietary FloDisc® Technology sets us apart in powder handling conveyors.

From our factory in Perth, Western Australia, we design, engineer, manufacture, and distribute our conveyors and process line technology.

Floveyor specialises in powder handling applications for emerging industries like Critical Resources and mature markets such as Agribusiness and Food and Beverage.

Our team adapts each project to meet the unique materials handling challenges and plant design requirements of our customers.

Heritage matters

We began as grassroots inventors inspired by classic technologies. Today we’re world leaders in powder handling.

1958

The First Floveyor

The first Floveyor ever build, Finlay’s nut processing plant, Perth, Western Australia.

1962

Floveyor goes mobile

Mobile Plunge Feed Floveyor, CBH for loading of wheat into trucks, Western Australia.

1963

Floveyor discovered to pump water

Floveyor removed sediment from farm dams and found to pump water brilliantly.

1964

Floveyor helps with cleanup after a rail crash

Mobile Plunge Feeder Floveyor cleans up after derailment, Northam, Western Australia.

1965

Floveyor goes into industry

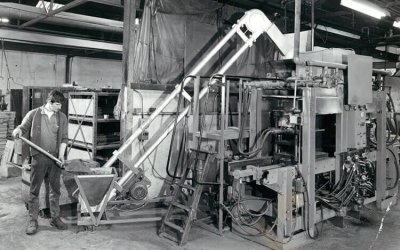

Floveyor breaks through into industry operating a foundry in New South Wales.

1970

Floveyor enters Africa

Floveyor handling river bed fines into a screening operation for tin mining in Kenya.

1978

Floveyor refines the food industry

UK exhibition to promote new design considerations for the food industry.

1988

Floveyor enters Japan

Floveyor breaks into the Japanese market and remains highly regarded.

1989

Floveyor brothers in the ’80s

Second-generation Walker engineers in photo shoot after winning the Small Business Award.

1992

Floveyor shows versatility

Floveyor filling packaging machine in small process plant, Victoria.

1998

Floveyor goes mainstream in manufacturing

Allied Group incorporate Floveyor into their operations, New South Wales.

2000

Floveyor’s global footprint

Dynea/AICA Floveyor handling urea and melamine throughout their Australasian operations.

2004

Daily diversity in powder handling

Orica handles numerous products in various plants across Australia.

2005

Floveyor reliability and availability

Mixing, blending, and packaging system for Australian Mud, Perth, Western Australia.

2010

Floveyor in flavour

Floveyor flavouring line pre-delivery testing, Bangkok, Thailand.

2010

Slashing tanker loading time

Sadleirs Logistics contracts sugar delivery to Coca Cola, Perth, Western Australia.

2012

Full powder delivery system

Incorporating over 80 Floveyor units, Perth, Western Australia.

2012

Floveyor under new ownership

Rhys Walker continues the Walker family business legacy.

2017

40Under40 Winner

Managing Director Rhys Walker receives WA Business News 40Under40 Award, Western Australia.

2018

Tanker Loader install for cement application

Floveyor F5 Endura with dual hopper, dust collection and additional features.

2021

Floveyor enters the battery minerals industry

We install process line of 10 Floveyors for nickel sulphate plant in Europe.

2021

Floveyor opens New Zealand office

We expand our international reach and introduce process line technology for global pet food markets.

2022

Floveyor rebrands product ranges

Floveyor launches its newly branded product ranges.

2023

3 Nominations for Telstra Best of Business Awards

Floveyor is recognised in three categories for Outstanding Growth, Sustainability and Embracing Innovation.

Floveyor through the years

Watch the video:

FloDisc® Technology

FloDisc® Technology sets us apart in powder handling conveyors.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

Floveyor

© 2022 Floveyor. All rights reserved. Privacy Policy