Allpress Espresso is a coffee roaster and espresso specialist founded in Auckland, New Zealand. Founder Michael Allpress began the business in 1986 when he wheeled his coffee cart into a local market. Today Allpress is a thriving global coffee company dedicated to connecting communities to great coffee produced in sustainable ways. They rely on Floveyor for bulk material handling of coffee beans – a coffee conveying solution using a combination of aero-mechanical conveyors (AMC) and tubular drag conveyor (TDC) distribution systems.

Coffee conveying: gentle transfer of green and roasted beans

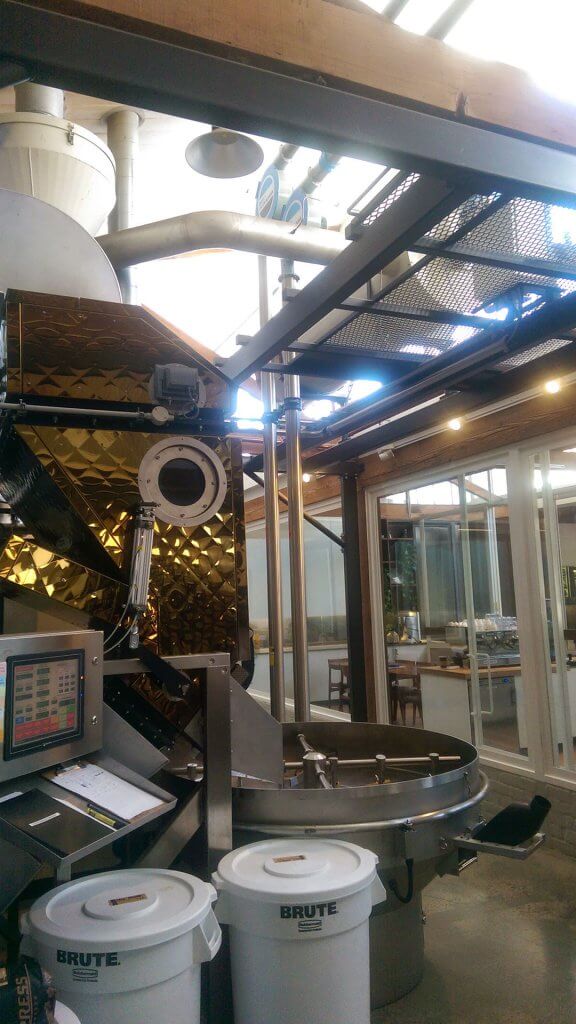

Allpress wanted to gently transfer green and roasted coffee beans in a variety of industrial layouts. As many of their trademark roasteries and cafés are in refurbished buildings, they needed equipment that worked well in tight places and could be configured for existing process lines.

As a high-grade food producer, Allpress has hygiene, total batch transfer and product integrity front and centre in their material handling needs. Operating in integrated retail and production environments, they wanted equipment that worked as well as it looked. The process line had to enhance Allpress’s cultural commitment to transparency by letting customers see their innovative Hot Air Roasting process.

Allpress requirements for coffee conveying

- Transferring beans horizontally and vertically

- Eliminating manual lifting of 30-70 kg sacks of green beans

- Maintaining blend integrity of coffee beans throughout the process

- Sleek design and high-quality manufacturing

- Improving worker safety.

Floveyor coffee conveying solution

After exploring a range of food-grade conveying options, Allpress’s team settled on Floveyor as the OEM who could help them optimise their process line. The solution includes:

- Floveyor Elementa F4

- Tubular Drag Conveyor Distribution System

- Bag tip station.

Allpress took Floveyor’s longevity in safe food and beverage conveying since 1958 into consideration, along with their reputation and experience in bulk material handling of coffee beans and coffee products. With Floveyor being the inventors of the aero-mechanical method of conveying and FloDisc® technology, Allpress knew they were in safe hands for rapid, safe and gentle transfer of materials for vertical angles.

The AMC wasn’t enough – Allpress needed a food-grade drag conveyor. Floveyor’s TDC distribution system solved Allpress’s second problem of being able to gently move beans horizontally across complex routes. Green beans are efficiently transferred to three large siloes using the TDC’s multiple discharge points. Because the two conveying systems can be integrated, Allpress was confident they’d found their solution.

Floveyor met the combined demands of tight fits, quirky locations and fixed plant, even with every location being different. Each coffee conveying solution provides:

- A small footprint

- High velocity for vertical throughputs

- Horizontal transfers into silos, with multiple discharge points.

Floveyor’s quiet, dust-free operation and minimal maintenance requirements blend seamlessly into the onsite roasting process without compromising the café experience of Allpress’s customers in any way.

Tubular drag conveyor with aero-mechanical conveying a winning combination

Nine custom-designed Floveyor coffee conveying solutions have been installed in multiple Allpress Roasteries across the globe.

The gentle aero-mechanical method of conveying with FloDisc technology preserves the premium condition of gourmet green and roasted coffee beans at both ends of the process. The TDC transfers coffee beans horizontally across complex routes and allows for multiple discharge points to efficiently fill siloes.

Advantages of Floveyor conveying systems for coffee roasteries:

- Handles friable and blended products without degradation

- Total batch transfers maintain consistency and minimise product wastage

- Increased production

- High availability

- Easy cleaning and maintenance

- Improved worker safety with reduced manual handling of bags

- Fully enclosed, dust- and contamination-free conveying

- Quiet operation with no need for dust extraction or filters

- Small footprint, highly configurable for existing process lines

- Energy efficient, low operating costs

- Low total cost of ownership.

For more information about Floveyor powder handling systems

If you would like to know more about aero-mechanical conveying with FloDisc Technology or about tubular drag conveying, get in touch with Floveyor. As powder handling specialists, we have complete conveying and distribution systems for powders, granules, fibres, flakes, seeds, beads, and pellets.