Capital investment in process line machinery

How do you know if your capital investment in process line machinery will pay off? A leading food manufacturer in Africa did not anticipate the decision they made in 1983 would have a long-term, positive impact on their organisation. That initial decision for a newly engineered conveyor from Floveyor continues to increase the return on their investment.

At the time of the initial purchase, the company had been milling wheat flours for more than 120 years. The company is now part of an African food producing giant that manufactures a wide range of branded and private label food products, most of which use milled wheat flours.

Industry demand influences Floveyor’s engineering schedules

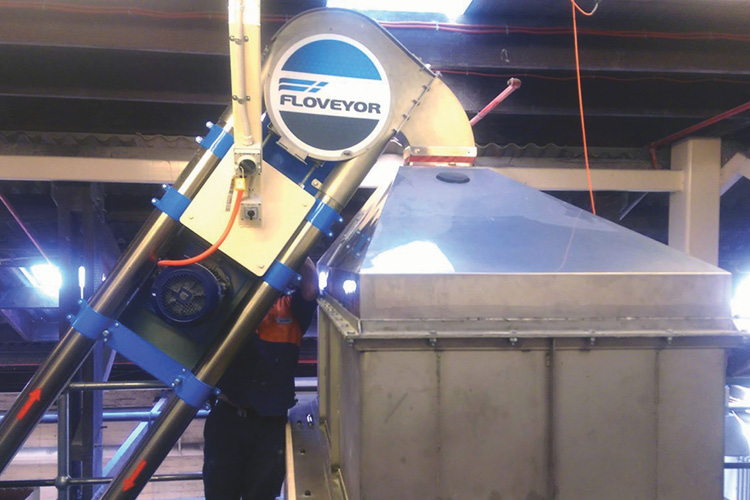

Floveyor was in the final stages of testing of its F5 conveyor when the flour mill contacted them about high-capacity conveyors using the aero-mechanical method of powder handling (AMC). The company needed conveyors with capacity to match or exceed a minimum of 15 tph. Since larger throughput had become an increasingly common request, Floveyor engineers had already designed the F5 conveyor, but it wasn’t yet available to the public.

Testing and production timetables were brought forward so the F5 would be available to meet the food processor’s production schedule. Like the popular F3 and F4 conveyors, the F5 was designed to be energy efficient and manage the contained transfers of powders and granules. Four of the newly minted F5 machines were delivered to the mill to accommodate demand for their food products. The machines were installed in 1983.

ROI exceeds Floveyor purchase price, many times over

Fast-forward to today and the original F5 conveyors still operate flawlessly with minimal maintenance. The F5 conveyors have been in continual operation at the plant for more than four decades, owing largely to the way Floveyor has engineered their machinery for durability and longevity.

Compatible parts have been supplied over the years to accommodate design updates required by the ever-changing food industry standards. While the payback period for the food processor’s investment occurred many decades ago, the return on investment continues to improve every day the Floveyor process line machinery is in operation. What’s more, a process line using Floveyor machinery and equipment makes a favourable impression in the event of mergers and acquisitions, due to the low cost of ownership and long-term reliability of the conveyors.

Floveyor engineering improvements continue

New F5 Floveyors have capacities of up to 105 tph over distances of 16 metres. Floveyor continues to refine the capabilities of the F5 workhorse, making it one of the most sought-after conveyors in the world. Every day F5 Floveyors handle applications ranging from high-speed process line conveying to bulk tanker loading to filling silos. Due to the F5’s ability to transfer a diverse range of powders and granules, coupled with high-speed conveying, the conveyors are in operation in food and beverage, chemical, manufacturing, mining, and agricultural industries all over the world.

For more information about conveyors and process line technology

If you’d like to find out how choosing Floveyor can help you improve your ROI for decades to come, get in touch. As powder handling specialists, we can advise you on the best machinery and equipment to keep your plant running for years.