Home » Agricultural Conveying » Animal Nutrition

Meeting the challenges of animal nutrition handling

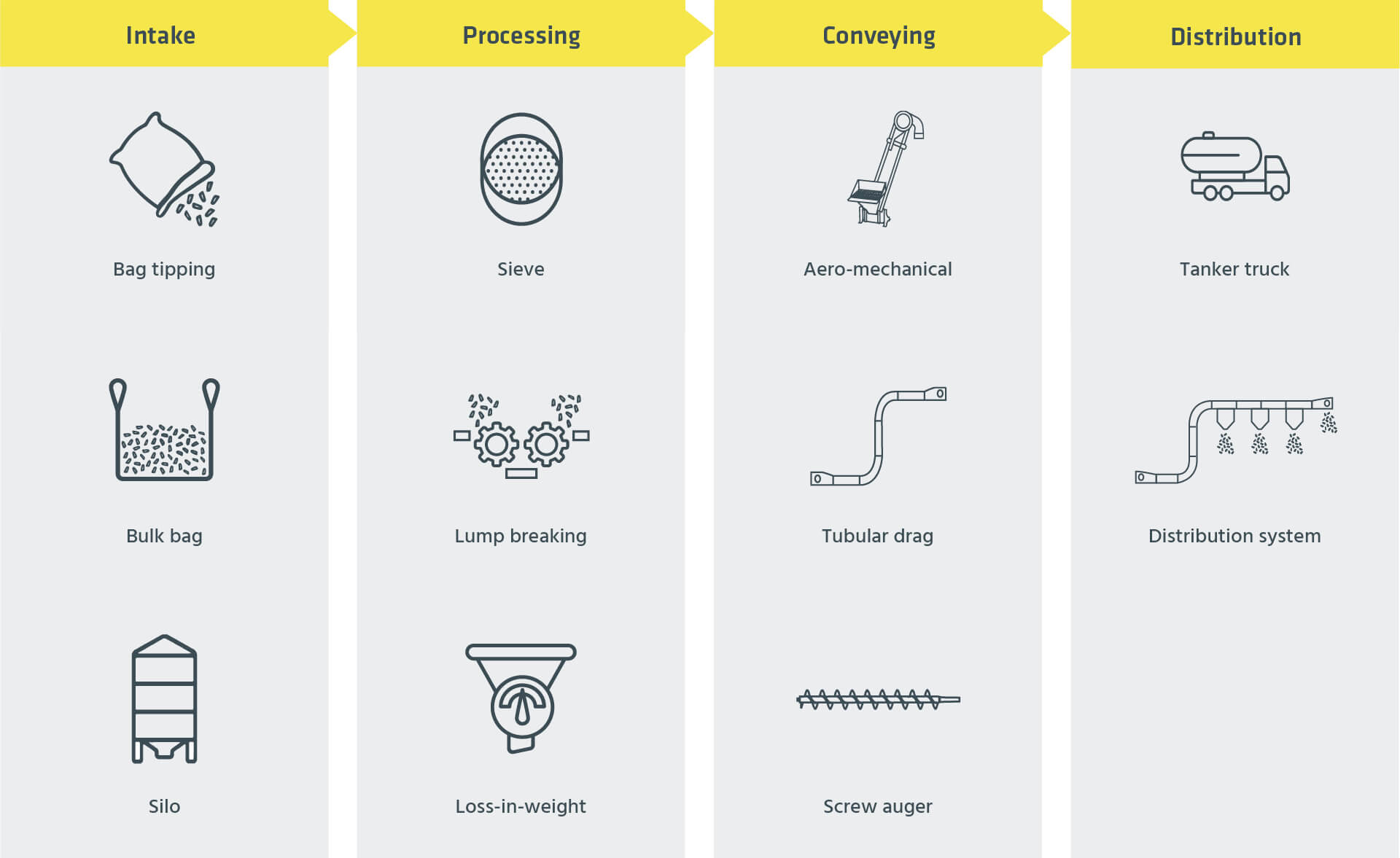

When it comes to animal nutrition conveying, there are a host of challenges with pellet, flake or meal ingredients in processing. As with pet food conveying, producers face issues of product contamination, product degradation, and separation of mixes and blends. So how can animal feed producers maintain nutritional value and product integrity while meeting production demands?

An aero-mechanical conveyor (AMC) using FloDisc® Technology is a gentle, rapid, and safe way to handle animal nutrition. Floveyor engineered the fully enclosed food-safe design to eliminate contamination threats and prevent the impact of moisture and dust, even at high throughputs. It’s why Floveyor is the ideal choice for cost-effective bulk material handling of animal nutrients.

Material characteristics

Fine particles

Dust control, agglomeration, fluid-like leakage issues

Aggregate blends

Handling difficulties with fine and large particles

Cohesive materials

Compaction issues, difficult discharge

Our products for conveying animal nutrition

Conveyor ranges

Avida

Zuverlässige, schnelle Auftragsabwicklung mit niedrigen Betriebskosten

- Bis zu 30 TPH

Elementa

Compliance and quality assurance for low-risk, dry food stuffs

- Bis zu 54 TPH

- Chemisch reinigen

- Nass sauber

- Zertifiziert nach amerikanischen FDA- und EU EC-Vorschriften

- ATEX 21

Process line technology

Dosierschneckenförderer

Dosing Screw Feeders (DSF) are designed to accurately meter or dose bulk material.

AMC Screw Feeder

Aero-Mechanical Screw Feeders (ASF) are designed specifically to feed bulk material into a Floveyor aeromechanical conveyor (AMC).

FIBC Unloading Screw Feeder

FIBC Unloading Screw Feeders are designed specifically to unload either disposable or reusable Flexible Intermediate Bulk Containers (FIBCs).

Reusable FIBC Unloader

Reusable FIBC Unloaders are designed to safely and reliably unload reusable (multi-trip) Flexible Intermediate Bulk Containers (bulk bags).

Einweg-FIBC-Entlader

Disposable FIBC Unloaders are designed specifically to decant disposable (single-trip) flat bottom FIBCs.

Trogschneckendosierer

Trough Screw Feeders (TSF) are suitable for installs that require feeder metering from multiple sources to a single discharge.

Rotierender Klumpenbrecher

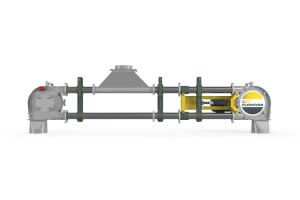

The Rotary Lump Breaker (RLB) is designed for the simple deagglomeration of compacted material into smaller particles.

Bi-Directional AMC

Reusable FIBC Tanker Loader

Disposable FIBC Tanker Loader

FIBC Tanker Loader with Dust Extraction

Why Floveyor

Floveyor invented the aero-mechanical method of conveying and has been evolving powder handling for 65 years. In addition to animal nutrition, a single Floveyor can transfer and elevate thousands of food-grade powders and granules in your processing plant. Our tubular drag conveyor (TDC) is ideal for complex routes and multiple discharge points. Floveyor conveyors are easy to clean, provide total batch transfers, and are available for hazardous applications and in mobile units. Whether you have a greenfield operation or need process line technology to integrate with your existing operation, Floveyor has the conveying technology you need to keep your plant running safely and efficiently for decades to come.

Discover the Floveyor advantage for animal nutrition handling, already trusted by a diverse customer base across the globe.

Animal nutrition conveying success stories

The FloDisc Technology difference

When you take everything into account for optimal agricultural materials processing, only one conveyor meets all the requirements – Floveyor with FloDisc.® Technology

Operate at peak capacity

Floveyor has optimised bulk animal nutrition processing in hundreds of plants around the world. Let’s work together to make sure your plant is operating at peak efficiency and safety with conveyors and process line technology from powder handling specialists.

Send us your product for testing

Watch our material tests for animal nutrition. Or get in touch with our powder handling specialists to arrange a test for you using your own product.

Floveyor ist auf die Entwicklung und Herstellung von Maschinen und Anlagen für den effizienten Schüttgutumschlag von Pulvern und Granulaten spezialisiert.

© 2022 Floveyor. Alle Rechte vorbehalten. Datenschutzrichtlinie