- Productos

- Industrias

- Obtener un presupuesto

- Blog

- Acerca de

- Contacte con

- Productos

- Industrias

- Obtener un presupuesto

- Blog

- Acerca de

- Contacte con

Home » About

Conveyor manufacturer for powder handling

If you’ve ever eaten a cake, enjoyed a cola, or coated a wall with paint, chances are Floveyor played a part in getting those products into your hands. Our first invention, the aero-mechanical conveyor (AMC), transformed powder handling and we continue to meet the demands for industrial conveying of powders and granules.

From our factory in Perth, Western Australia, we design, engineer, manufacture, and distribute our conveyors and bulk material handling equipment. We partner with major global brands and small manufacturers alike to build efficiency and safety into their process routes while ensuring product integrity and maximum yields during transfer.

Por qué Floveyor

Floveyor has been delivering conveyor machinery and equipment for more than 65 years and we haven’t met a challenge we couldn’t solve. Our proprietary FloDisc® Technology and an innovation mindset sets us apart as conveyor manufacturer and powder handling specialist. A commitment to quality, customer service, and engineering excellence is the key to our success as an OEM of high-quality, durable powder conveying systems.

The FloDisc® Technology difference

The aero-mechanical conveyor from Floveyor is uniquely engineered to optimise powder handling including powders, granules, flakes, seeds, pellets, beads, and nuts. FloDisc Technology uses centrifugal force to suspend raw materials in an air pocket, then efficiently propel them to a collection point through a fully enclosed tube. Only Floveyor AMCs with FloDisc can maintain product integrity, ensure operator safety, and maximise energy efficiency at high throughputs.

Quality standards

Floveyor designs, engineers, and manufactures to the highest standards of safety, quality, and cleanliness. We cater to the requirements of specific industries and industrial applications.

- Meets the European ATEX 2014/34/EU directive, suitable for potentially explosive atmospheres

- IECEx compliance

- Listed in EHEDG Guideline 36, one of only five food safe conveying systems

- Standards-based design in accordance with AS/NZS/ISO/EN

- Designed, engineered and manufactured to GMP, AMI and 3-A guidelines

- All materials in product contact areas are traceable and certified to American FDA and EU EC regulations.

How we work

Floveyor works closely with customers to deliver conveying systems that are perfectly suited to the application and installation. We recognise that every process line is different, so every powder handling solution must be optimised to meet our high standards for quality, operator safety, energy-efficiency, and product integrity.

Engineering services

Floveyor engineers play an integral part in our manufacturing process. They work closely with our powder handling specialists to ensure every solution we develop meets the needs of the customer, and they’ll work directly with customers to solve complex powder handling challenges.

Design and fabrication

All Floveyor machinery and equipment goes through rigorous design, fabrication and quality assurance processes in our factory in Perth, Western Australia. This ensures the highest quality standards are achieved and each conveying solution exceeds expectations when operational and provides a low total cost of ownership.

Commissioning

Floveyor conveyors are designed for easy installation and maintenance. We offer commissioning support for large installations and complex routes, to ensure your new Floveyor conveyor system delivers immediate value to your operation.

After sales support

Floveyor’s team of powder handling specialists and engineers are always on hand for after sales support. We have a large stock of spare parts to ensure your process line operates at maximum efficiency. We have a global support network to facilitate fast intervention for the reliable, safe, and economic operation of your process line.

Our history

We began with a single invention, the aero-mechanical conveyor. Today we’re world leaders in powder handling solutions. Floveyor conveying systems are used in more than 6,000 operations around the world, across multiple industries and applications.

1958

The First Floveyor

El primer Floveyor construido, planta de procesamiento de frutos secos de Finlay, Perth, Australia Occidental.

1962

Floveyor se desplaza

Transportador móvil de alimentación por inmersión, CBH para carga de trigo en camiones, Australia Occidental.

1978

Floveyor perfecciona la industria alimentaria

Exposición en el Reino Unido para promover nuevas consideraciones de diseño en la industria alimentaria.

1988

Floveyor entra en Japón

Floveyor irrumpe en el mercado japonés y sigue gozando de gran prestigio.

2012

Sistema completo de suministro de polvo

Incorporación de más de 80 unidades Floveyor, Perth, Australia Occidental.

2021

Floveyor entra en el sector de los minerales para pilas

Instalamos una línea de proceso de 10 Floveyors para una planta de sulfato de níquel en Europa.

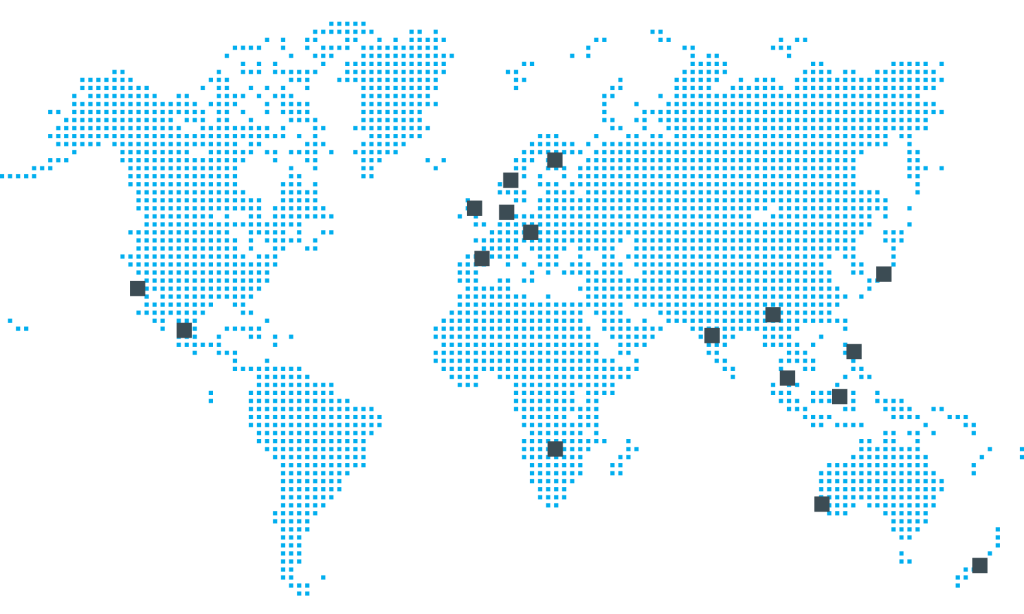

Our partner network

The Floveyor global partner network ensures customers receive local support to reduce down time and improve overall availability.

Póngase en contacto con Floveyor

Póngase en contacto con un especialista

Más información sobre la optimización de la manipulación del polvo.

Consultas sobre servicios

Obtenga ayuda con las consultas sobre piezas y mantenimiento.

Floveyor se especializa en la ingeniería y fabricación de máquinas y equipos para la manipulación eficiente de materiales a granel de polvos y gránulos.

©