Home » Food and Beverage Conveying » Dairy Conveyor

Meeting the challenges of milk powder products handling

Because dairy powders are used in so many food and beverage recipes all over the world, they require hygienic conditions and industrial-grade performance. Atmospheric changes can lead to increased moisture which promotes caking and clumping, softening, and compaction — and they can all lead to product degradation. Milk powders are known to leave product build-up in conveying equipment which reduces availability and increases cleaning time. Dust is also a concern, not least because it can lead to an explosion.

The aero-mechanical method of conveying (AMC) using FloDisc® Technology is a gentle, rapid and safe way to handle bulk dairy powder products. Floveyor engineered the fully enclosed design to prevent the impact of moisture and dust while preserving the integrity of your materials. It makes Floveyor the ideal choice for a dairy conveyor for the safe, bulk material handling of milk powders at high throughputs.

Material characteristics

Fragile materials

Requires gentle handling, limits system types

Bacteria prone

Requires controlled handling, cleaning challenges

High fat content

Adhesion to surfaces, clogging and cleaning challenges

Our products for milk powder products handling

Conveyor ranges – Dairy conveyor

エレメンタ

Compliance and quality assurance for low-risk, dry food stuffs

- 最大54 TPH

- ドライクリーニング

- ウェットクリーン

- 米国FDAおよびEU EC規制の認定を取得

- ATEX 21

ヌートリア

Clean design benefits for sophisticated food processing

- 最大30 TPH

- ドライクリーニング

- ウェットクリーン

- 米国FDAおよびEU EC規制の認定を取得

- ATEX & IECEx Zone 21

プラ

グローバルな食品安全の厳しい要求に応えるために設計された

- 最大30 TPH

- 米国FDAおよびEU EC規制の認定を取得

- GMP設計

- EHEDGガイドラインに準拠

- ドライクリーニング

- ウェットクリーン

- CIPウェットクリーン

- 蒸気滅菌

- ATEX & IECEx Zone 21

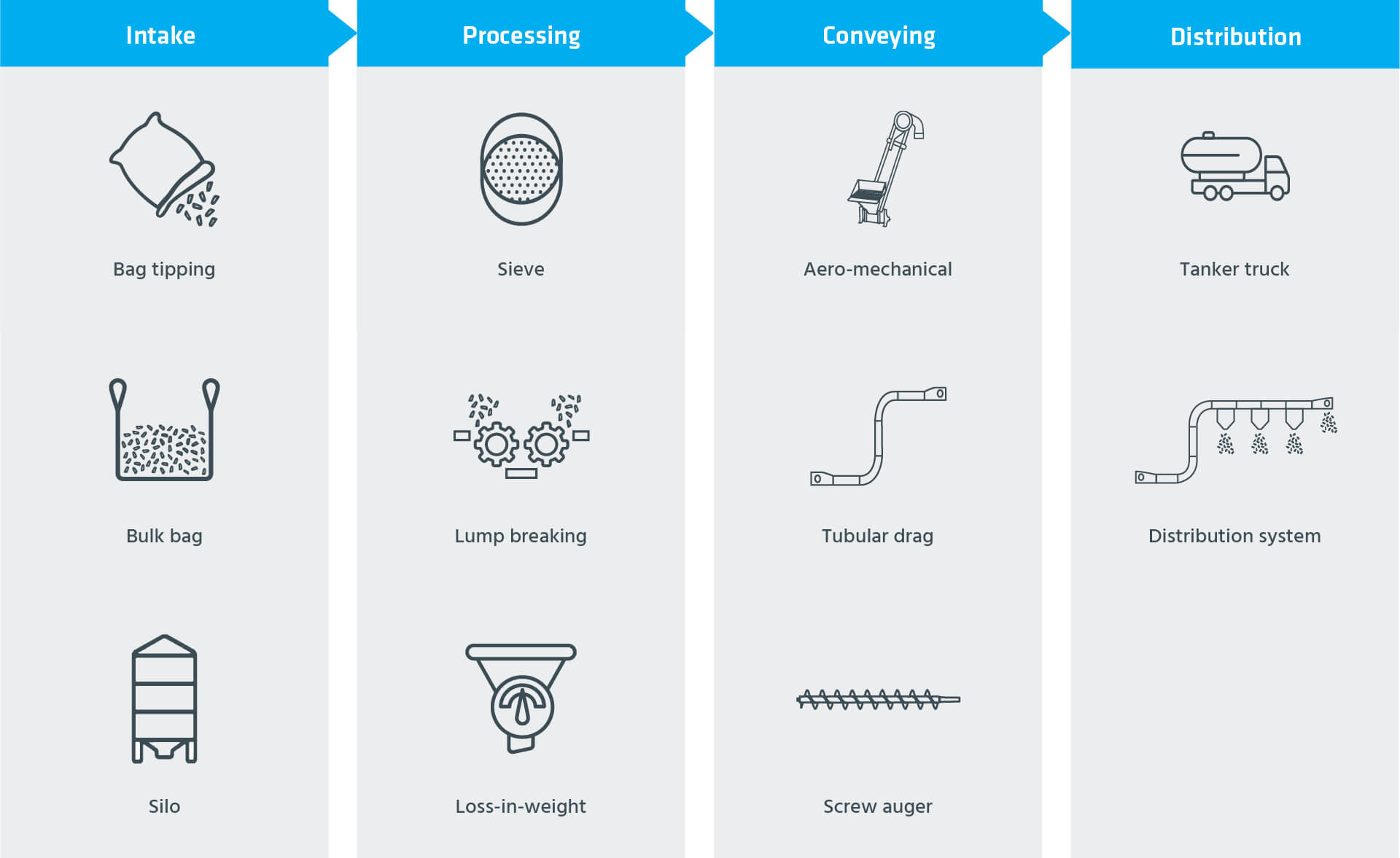

Process line technology

投薬用スクリューフィーダー

Dosing Screw Feeders (DSF) are designed to accurately meter or dose bulk material.

AMC Screw Feeder

Aero-Mechanical Screw Feeders (ASF) are designed specifically to feed bulk material into a Floveyor aeromechanical conveyor (AMC).

FIBC Unloading Screw Feeder

FIBC Unloading Screw Feeders are designed specifically to unload either disposable or reusable Flexible Intermediate Bulk Containers (FIBCs).

Reusable FIBC Unloader

Reusable FIBC Unloaders are designed to safely and reliably unload reusable (multi-trip) Flexible Intermediate Bulk Containers (bulk bags).

使い捨てFIBCアンローダー

Disposable FIBC Unloaders are designed specifically to decant disposable (single-trip) flat bottom FIBCs.

トラフ型スクリューフィーダー

Trough Screw Feeders (TSF) are suitable for installs that require feeder metering from multiple sources to a single discharge.

ロータリーランプブレーカー

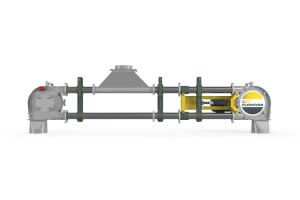

The Rotary Lump Breaker (RLB) is designed for the simple deagglomeration of compacted material into smaller particles.

Bi-Directional AMC

Reusable FIBC Tanker Loader

Disposable FIBC Tanker Loader

FIBC Tanker Loader with Dust Extraction

Why Floveyor

Why Floveyor? Floveyor invented the AMC and has been evolving powder handling for 65 years. A single Floveyor can rapidly transfer and elevate thousands of food-grade powders and granules using fully enclosed tubes. Our tubular drag conveyor (TDC) is ideal for complex routes and multiple discharge points. Floveyor conveyors are easy to clean, can be manufactured with polymer-coated ropes that are X-ray detectable, and are available for hazardous applications and in mobile units. Whether you have a greenfield operation or need process line technology to integrate with your existing food and beverage operation, Floveyor has the conveying technology you need to keep your plant running safely and efficiently.

Discover the Floveyor advantage for dairy and milk powder handling, already trusted by a diverse customer base across the globe.

Dairy conveyor success stories

The FloDisc Technology difference

When you take everything into account for optimal food and beverage materials processing, only one conveyor meets all the requirements – Floveyor with FloDisc.® Technology

Getting a handle on dairy powders

Floveyor has optimised bulk material handling for dairy powders in hundreds of food processing plants around the world. Let’s work together to make sure your plant is operating at peak capacity and safety, with dairy conveyor and process line technology from powder handling specialists.

Send us your product for testing

There’s no need to cry over spilled milk powder. Get in touch with our powder handling specialists to arrange a test using your own product. In the meantime, check out our R&D video testing skimmed milk powder.