Download our White Paper:

Optimising Lithium Hydroxide Monohydrate

Powder Handling

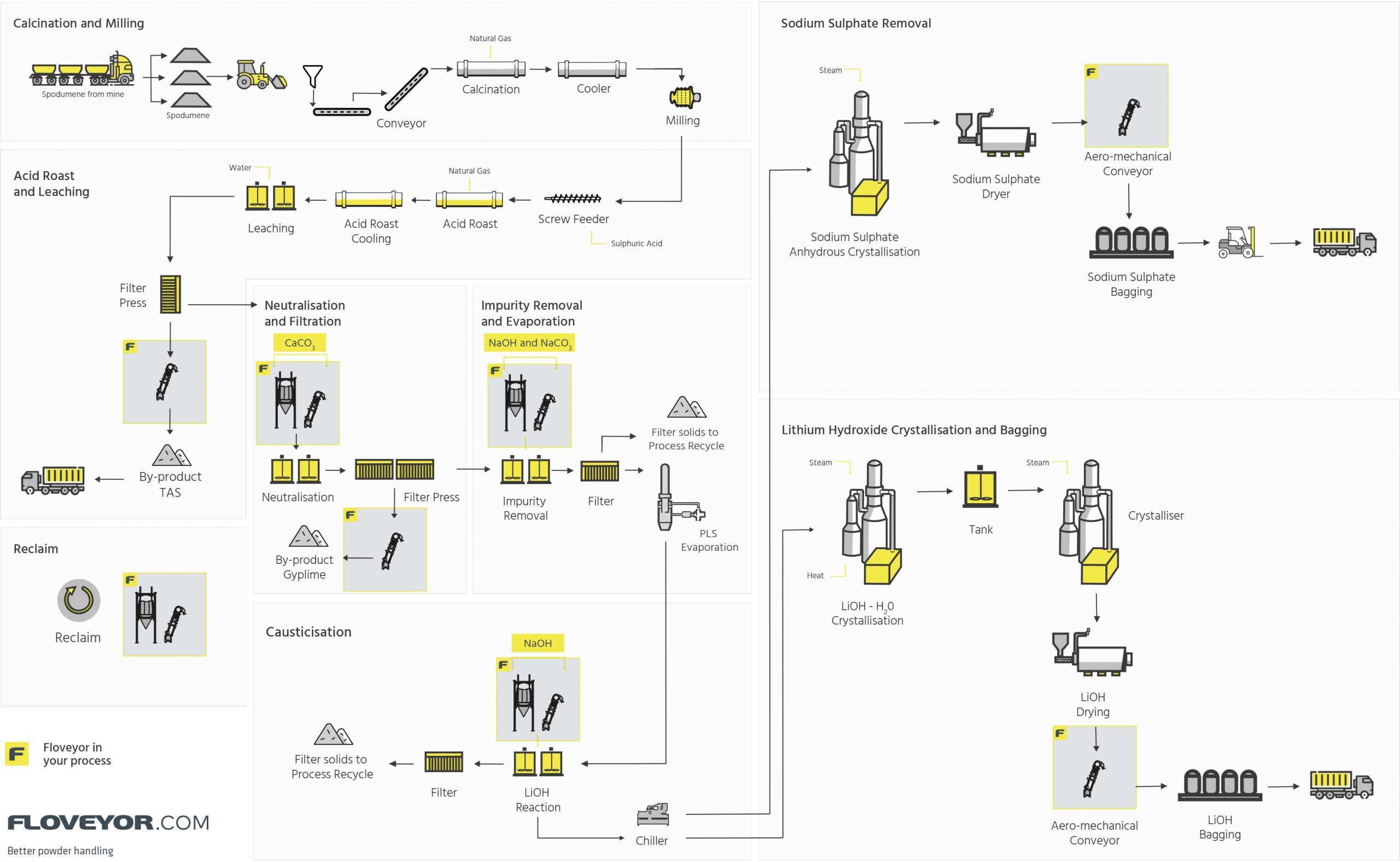

Processing battery minerals comes with stringent requirements. This white paper provides analysis of the suitability of common conveyors used in mining and recommendations for how to select an optimal conveying system for high-yield plants.