Home » Manufacturing Conveying » Paper, Pulp and Wood

Meeting the challenges of paper, pulp and wood conveying

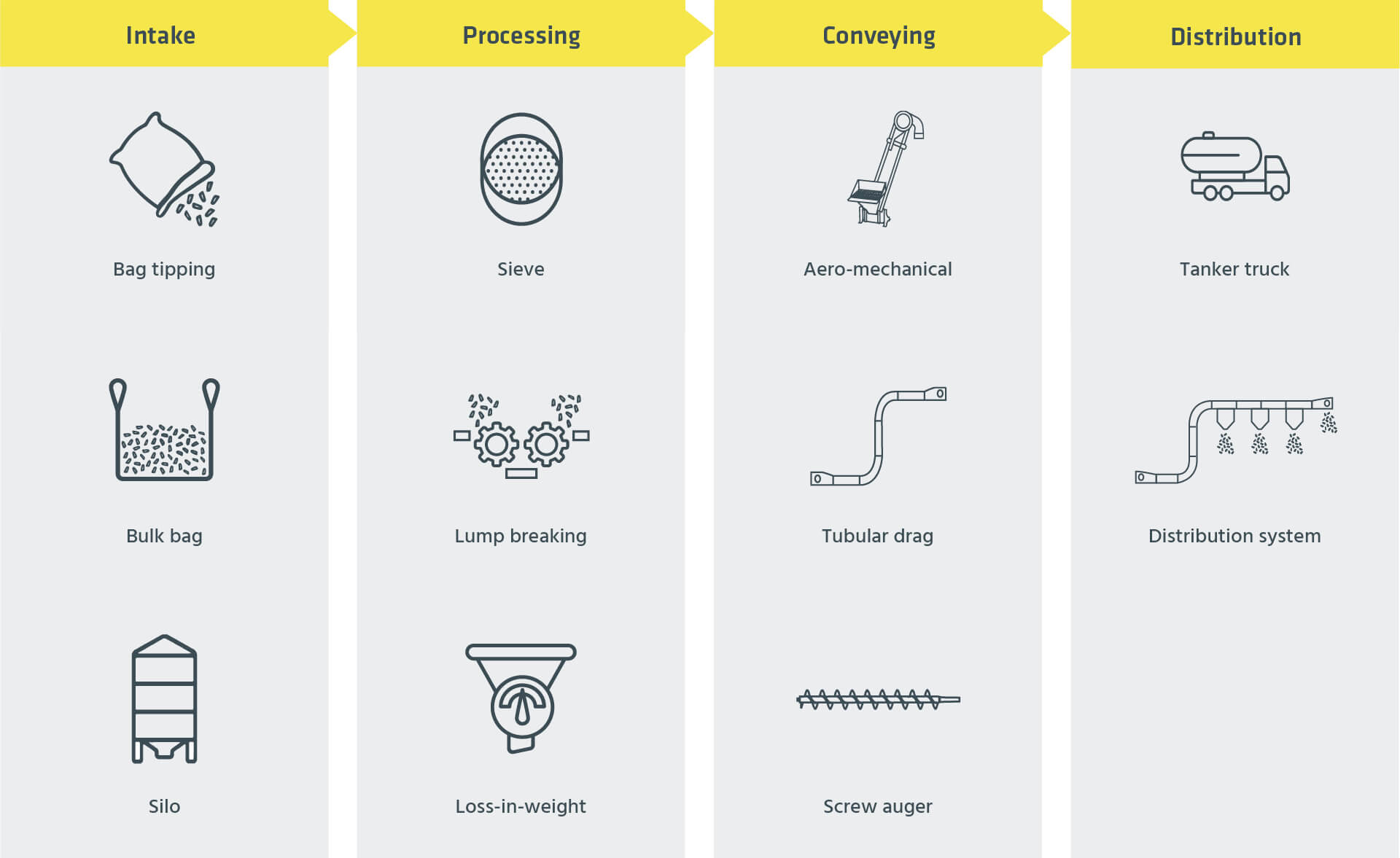

Bulk material handling for paper, pulp and wood products requires tough machinery that can stand up to corrosion, abrasion, moisture and high levels of naturally occurring acid. Durability is paramount, especially for operations that require around-the-clock processing. Is there a cost-effective way to convey paper, pulp and wood materials? We think so.

An aero-mechanical conveyor (AMC) using FloDisc® Technology keeps downtime to a minimum while conveying paper, pulp and wood materials. Floveyor engineered the fully enclosed design with stainless steel tubes and minimal moving parts to handle even the most abrasive products, with minimal maintenance. Energy-efficient conveying contributes to ESG initiatives and keeps processing costs down. That’s why Floveyor is the ideal choice for bulk material handling of paper, pulp and wood products

Material characteristics

Low density

Requires larger equipment, increased footprint

Abrasive materials

Accelerates equipment wear, more maintenance

Explosive / Hazardous

Stringent safety measures, explosion-proof needs

Our products for conveying paper, pulp and wood

Conveyor ranges

Avida

Reliable, rapid order fulfillment with low cost of ownership

- Up to 30 TPH

Robusta

When safety and durability are critical

- Up to 30 TPH

Endura

Effortless integration with complex applications and sites

- Up to 54 TPH

- Dry clean

- Wet clean

- ATEX & IECEx Zone 21

Bulk material handling equipment

Why Floveyor

Floveyor invented the AMC and has been evolving powder handling for 65 years. In addition to paper, pulp and wood, a single Floveyor can transfer and elevate thousands of powders and granules in your processing plant, at any elevation. Our tubular drag conveyor (TDC) is ideal for complex routes and multiple discharge points. Floveyor conveyors are energy efficient, durable, operate quietly, and are available for hazardous applications and in mobile units. Whether you have a greenfield operation or need process line technology to integrate with your existing operation, Floveyor has versatile conveying technology you need to keep your plant running with minimal maintenance required.

Discover the Floveyor advantage for paper, pulp and wood material conveying, already trusted by a diverse customer base across the globe.

The FloDisc Technology difference

When you take everything into account for optimal manufacturing materials processing, only one conveyor meets all the requirements – Floveyor with FloDisc® Technology.

Durable, energy-efficient conveying

Floveyor has optimised bulk materials handling for paper, pulp and wood processing plants around the world. Let’s work together to make sure your plant is operating sustainably with durable conveyors and process line technology from powder handling specialists.

Send us your product for testing

Watch our material tests for paper, pulp and wood. Or get in touch with our powder handling specialists to arrange a test for you using your own product.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©