Home » Critical Minerals Conveying » Battery Minerals

Meeting the challenges of battery minerals conveying

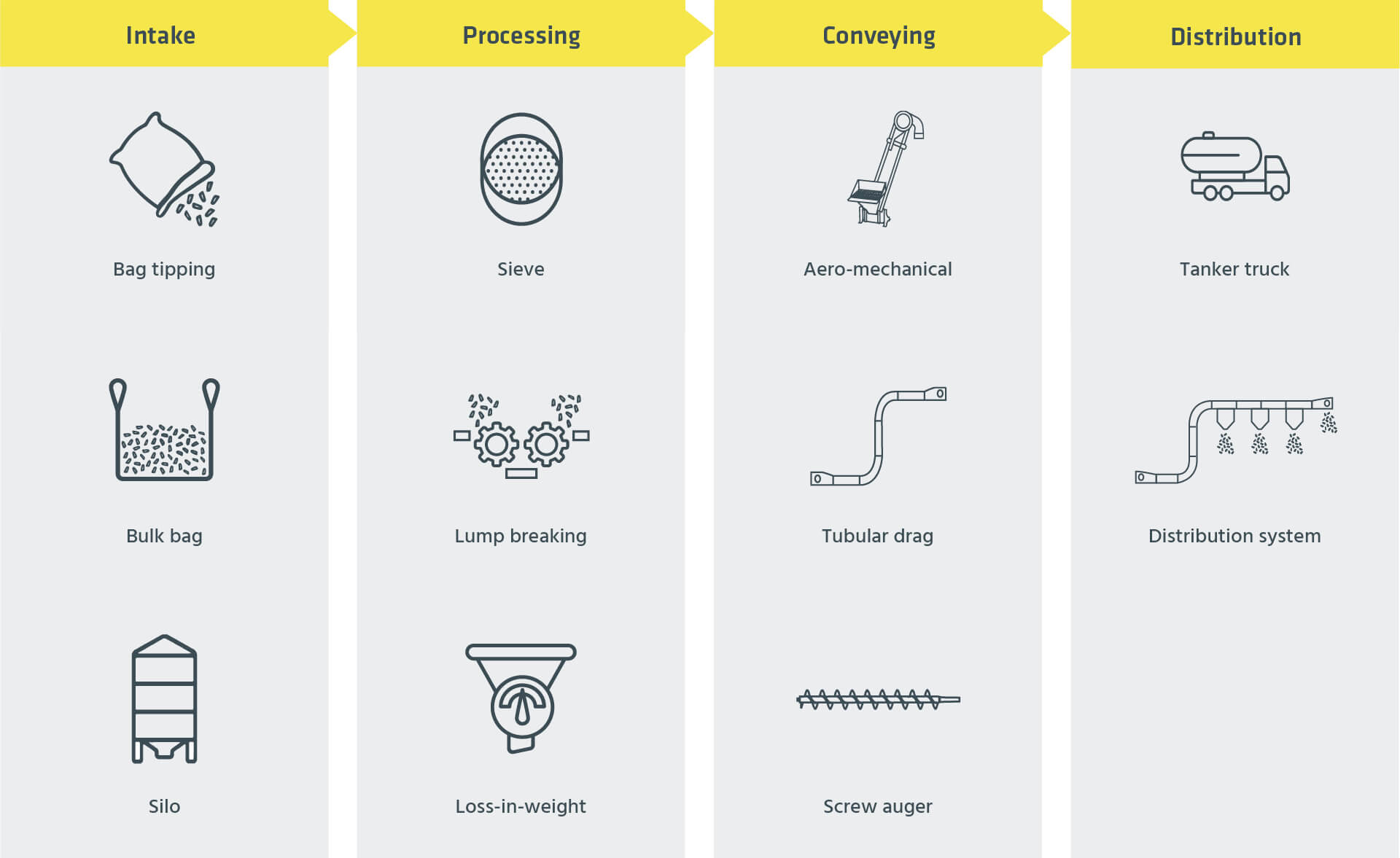

Understanding how to optimise powder handling for battery minerals conveying systems is key to designing and operating high-yield midstream processing operations. But battery minerals, especially lithium hydroxide, are easily degraded, susceptible to water, highly corrosive and reactive to carbon dioxide. How can you keep your operators safe and maximise your yield?

An aero-mechanical conveyor (AMC) using FloDisc® Technology is a rapid, gentle, and safe way to handle battery minerals. Our tubular drag conveyor (TDC) is ideal for complex routes and multiple discharge points. Our fully enclosed designs areengineered to mitigate the risk of ferrous and CO2 contamination and provide an excellent foundation for high-yield midstream battery minerals processing. Floveyor conveying systems require little maintenance and can be trusted to reliably provide high throughputs without damaging the crystalline structure of LiOH.H20.

Material characteristics

Fluid-like powders

Flooding, uncontrolled flow, dust control, segregation challenges

Fragile materials

Requires gentle handling, limits system types

Complex traits

Multiple handling challenges, increased operating costs

Our products for conveying battery minerals

Conveyor range

Endura

Effortless integration with complex applications and sites

- Up to 54 TPH

- Dry clean

- Wet clean

- ATEX & IECEx Zone 21

Bulk material handling equipment

Why Floveyor

Floveyor invented the AMC and has been evolving powder handling for 65 years. In addition to battery minerals, a single Floveyor can transfer and elevate thousands of sensitive and valuable powders and granules in your process. Our conveyors are easy to clean, operate quietly, and are available for hazardous applications and in mobile units. Whether you have a greenfield operation or need process line technology to integrate with your existing operation, Floveyor has the conveying technology you need to keep your plant running safely and at maximum capacity.

Discover the Floveyor advantage for battery minerals handling, already trusted by a diverse customer base across the globe.

Critical minerals conveying success stories

The FloDisc Technology difference

When you take everything into account for optimal critical minerals processing, only one conveyor meets all the requirements – Floveyor with FloDisc® Technology.

Find out how to optimise your yield

We’re ready to show you how better powder handling can optimise your yield for the future of battery minerals processing and the shift to renewable energies.

Send us your product for testing

Watch our R&D tests for bulk materials handling. Or get in touch with our powder handling specialists to arrange a test for you using your own product.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©