On December 21st, Floveyor is observing another major milestone. Technical Director Richard Walker is retiring after 40 years of employment. He’s worked across many different areas during his tenure, including metal fabrication, production management, engineering design, R&D, and sales and marketing. He also spent considerable time as Managing Director before moving into the role of Technical Director.

Richard joined the company when his dad was at the helm and he leaves it with his son in the position of MD. No-one at Floveyor has been so involved, on so many levels, for as long as Richard. We took the opportunity before he leaves the building for the last time to get his thoughts on a 47-year career in materials handling. As usual, Richard was gracious and generous with his information and knowledge. We started by asking Richard the easiest of questions.

What role have you enjoyed the most?

I’ve done everything from sweeping the floor up to MD. The thing I’ve enjoyed the most is working with the engineers to develop Floveyor’s modern aero-mechanical conveyor (AMC) for industrial conveying and powder handling. It’s been great working with the whole team who are very like-minded people. They’re inspirational and think outside the box.

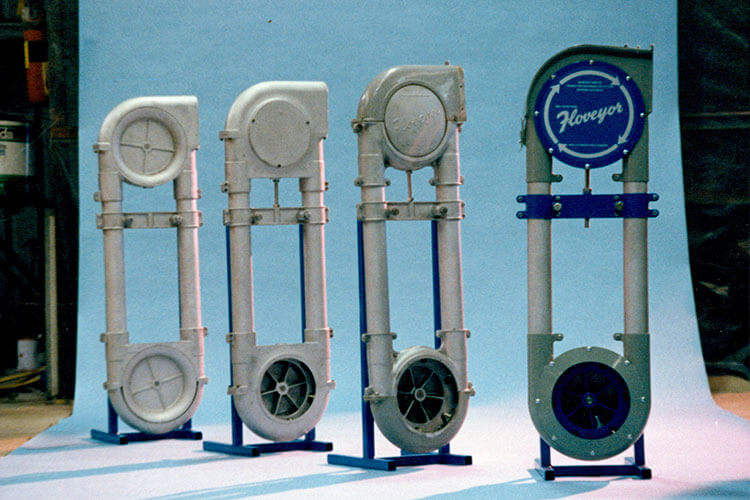

It’s just incredible to see how we’ve improved the aero-mechanical conveyor which we’d been manufacturing since 1963. We’d changed little things along the way but in 2016 we introduced a completely re-engineered conveyor to the market. It’s remarkable to see the quality of these machines. The stainless steel workmanship is excellent – the conveyors look beautiful. Revamping the entire manufacturing process also allowed us to improve manufacturing costs.

What were your top three career highlights?

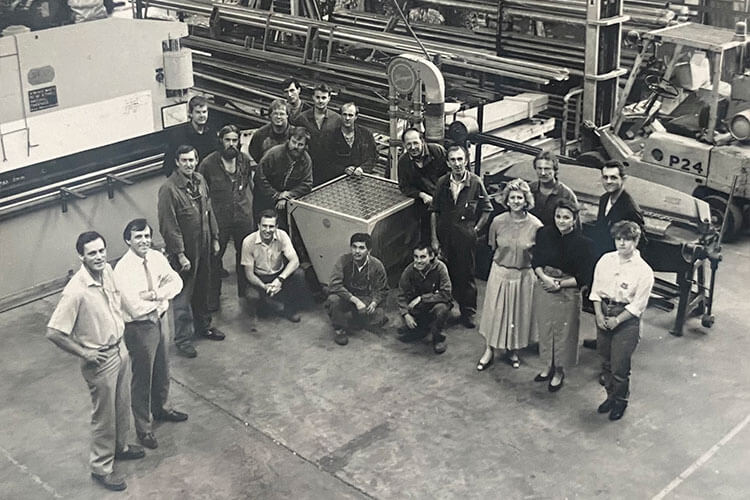

The first was winning the 1988 Telecom Small Business Award, because it put Floveyor on the map. The prize was a video package worth $30,000 which was quite an amount of money back then. We produced two videos of about five minutes each; one was a commercial and one was to support our sales team. They changed the business immediately and sales started going through the roof, along with brand recognition in the international marketplace. We had VHS tapes in those days and we were getting hundreds of them produced. Once people could see product disappearing down the hopper, or sugar disappearing or corn or wheat, it just transformed sales overnight.

The second highlight wasn’t at Floveyor. I left Floveyor in 1997 after I’d been with the business for 21 years. I took a job with SPIRAC Engineering, who makes shaftless screw conveyors. I was put on as a project engineer for a huge project in Singapore with 89 conveyors that cost about four and a half million dollars. I worked two and a half years on that project for everything from layout, design, and manufacturing. Because I had a manufacturing background, I oversaw the factory process and optimised a lot of their manufacturing processes. This was their only plant to go in without a single warranty claim. That was a real feather in my cap.

Finally, seeing the revamped Floveyor AMC we’re manufacturing now and reflecting on how much it’s changed is just incredible. Our workers have been fantastic. There’s one man who’s coming up to about 25 years of service. He started with us as an apprentice and the work that comes out of his hands now is superior, especially on that specialised stainless steel finishing. The team has done so well and that’s a big part of why I consider it a career highlight.

Richard as an inventor

A fitter and machinist by trade, Richard has always had an intense focus on building better machinery. A good example of his lasting contribution to powder handling is Floveyor’s polymer rope. Richard recognised an unmet demand in the market for contamination-free conveying, particularly from clients concerned about exposed wire coming in contact with food and consumable products.

Richard’s idea was to use an extruded wire which he swaged over the extrusion and discs and then injection-moulded over. This early design had issues with the swages moving under load, causing failures and problems. When the swages didn’t move, the extruded polymer wire could last for decades.

Richard spent a lot of time working with injection moulders, designing the tooling and the moulding process to hold the wire central while injection-moulding the coating over the wire and onto the discs. The two-stage injection-moulding process is highly intricate and required a significant amount of R&D to get right. The investment paid off. Thanks to Richard’s invention, Floveyor is a global market leader for conveying food stuffs.

What is your biggest accomplishment?

A focus on quality, beginning with manufacturing. I’ve chiseled away, made improvements, and added things. When I look at the operation when I started compared to now, it’s not the same business.

Equally important was introducing warranties and focusing on customer support and service. If something’s wrong, we just replace it straightaway. No question. There are Floveyor aero-mechanical conveyors that have been running for 45 years. We’ve heard of our ropes being used for more than 20 years. A flour mill in India had more than 80,000 hours of use on a rope assembly, which is more than eight times longer than we expect under ideal conditions. When we get feedback like that, it’s mind-blowing.

What is the most important risk you took?

The company was started by my father. Then my brother, Bob, and I ran the company together. In 2005, Bob was coming up to retirement. I wanted to buy him out of the business but my wife was not really excited by the idea. We spoke about it and she agreed – we used a combination of dividends and a bank loan, that wasn’t too prohibitive.

We actually bought the factory, equipment and all the IP. Bob shut down Production Machinery Company, the name of the original company. I always wanted to change our name so we opened Floveyor Proprietary Limited on 1 July 2005.

The feeling in the business changed immediately. We increased employee wages, started implementing quality measures, and focused on customer service.

Was it a good risk? Did it pay off?

Yes, especially once Rhys joined the company. I’m not that good at marketing and finance. I’m like my dad – an engineer at heart. Rhys is my son but I always told him if he wanted to come into the business, he had to approach me. I didn’t want to set an expectation for his career like our dad had done for Bob.

Rhys telling me that he’d like to come work for Floveyor would rate as one of my top career highlights. He’s hungry for information. From the first day, you’d only tell him something once. All the idiosyncrasies, the ins and outs – he grasped them straightaway and ran with them.

How has powder handling changed during your career?

Work conditions have changed dramatically. In the early days, there was little to no OH&S or a focus on worker welfare. The dust exposure was terrible and the explosiveness of dust is an absolute danger. Using Floveyor conveyors immediately sorted out a lot of the dust issues. A lot of businesses wouldn’t spend money on dust extractors, but the fully enclosed Floveyor was a big improvement for them.

We’ve never had a Floveyor explode, because they are inherently safe inside. You can have sparks inside, but we’ve never had one explode. A few world events like towns getting blown up in England from flour mills and sugar mills going up: It was those sorts of events that changed governments to becoming more accountable.

Some of the food factories you went into were shocking. Basically, there were two different types of food factories. There were the good-quality ones where they cared about their product and their brand reputation. There was a bit of dust in spots, but they cleaned, they hosed down, they did what they could. And then you had the other ones where you had rats and cockroaches. You think, I’m never buying that brand again. And that was the worst part about this industry. You’d go to places to quote and it put you off, particularly the food industry. There are probably 30% of businesses you wouldn’t buy from again, because you knew what their premises were like.

That’s all changed now. Government legislation has tightened up so much.

If you had to just pick one day that stood out, what was the most memorable day for you?

It would have to be winning that Telecom award in 1988 because it launched us. We had radio interviews, newspaper articles, product videos and commercials. Before that, no-one knew us. It was quite life transforming that one.

What do you see for the future of Floveyor?

Rhys is visionary; he’s looking at the future all the time. I see enormous potential for the company under his leadership. Rhys is always exploring how we can develop through the markets and what we can do with our technology. In the short term, I see Floveyor products being used in battery manufacturing.

I see continual improvement through engineering and working in R&D. Our engineers are working with our conveyors all the time. How can we improve this? How can we change the look? How can we make it friendlier, safer, and easier for operators to use? Every day it’s changing. So I see enormous potential on the product side.

What are you going to miss most about Floveyor?

It has to be the staff. I can’t talk to people easily. I can talk about Floveyor all day, but I’m not up with the latest in footy, or what’s happening on the political front. I’m not into that sort of thing at all. From a social point of view, I can go and chat to anyone here. I’ll miss that.

What are you going to do in retirement? What are your plans?

We’re going to Sydney in January to visit family. We haven’t bought a return ticket. We’ll hire a car and just go and catch up with friends. Then we’ll come back and finish off the last of renovations on our home.

Then we’ll do some travelling. We want to explore Queensland because we haven’t seen much outside of Brisbane. I have to go to China to say goodbye to our Chinese manager. He’s looked after me like family and we respect each other very highly. They’ve bent over backwards for us over the years. Then, a trip to Canada and the United States are at the top of our list.

My wife and I will be continuing our Christian walk which is a big part of our life. We’re waiting on God a bit. We have a few things we’re considering on that front, but nothing concrete yet. We’ll see what unfolds.

Is there anything else you’d like to add?

I’m 70 in March next year, so this retirement has been a long time coming, but it’s time. I know the engineering team is up to speed, well and truly. Rhys will be able to sort out most things and they can give me a call if they’ve got something that they’re totally stonkered on.

I’m still available for a consultation if they need it. No worries. I’ll still drop in and say hello and catch up from time to time.

Join us in congratulating Richard on 40 years of service to Floveyor and his contributions to advancing powder handling through innovation and engineering excellence. We’re going to miss him!