Bringing an old plant into compliance is a painstaking undertaking. But weeks and months of research, evaluation and product justification can evaporate when health and safety rules change. How can you futureproof your plant when regulatory bodies deliver unexpected news?

Hazardous material reclassifications are an unwelcome challenge in industrial manufacturing. Chemical substances go through rigorous testing to ensure they are safe for both humans and the environment in their intended applications. It’s one of the most critical considerations for any manufacturing operation. When regulations change, or when there’s a legal judgement against a consumer product, your entire plant can be impacted.

A recent reclassification of titanium dioxide, also known as TiO2, is a case in point. Out of an abundance of caution, the European Commission (EC) amended their regulations and standards and reclassified titanium dioxide as a “carcinogen category 2 by inhalation”, and have detailed “precautionary measures that need to be taken to minimise the hazard for human health”.

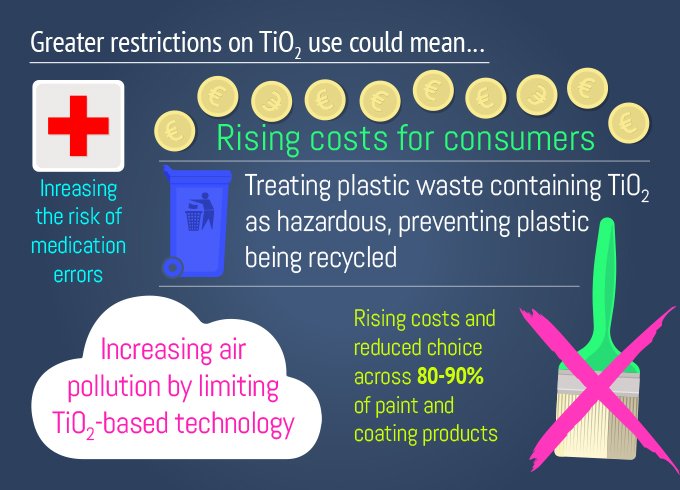

Employers have no choice but to implement better safety features. It comes at a cost both for manufacturers and consumers, as shown in this graphic supplied by TDMA (Titanium Dioxide Manufacturing Association).

In this case it’s the EC reclassifying TiO2. It would come as no surprise if the United States Department of Labor followed suit and tightened their Permissible Exposure Limit (PEL) for the powder. Potentially, any powder used in manufacturing could encounter the same situation.

Contained transfer futureproofs your powder handling operation

One way to mitigate these kinds of regulatory problems is to manage dust from the onset. Using a fully enclosed system to transfer powders and granules is the best way to circumvent the impact of future health and safety regulations.

Original Floveyor conveyors and accessory equipment are a good choice. As specialists in the AMC method of conveying, Floveyor has engineered its conveyors for a variety of industrial applications, including hazardous materials and those that easily generate dust.

Advantages include:

- Rapid transport of difficult materials – Sticky, hard to convey materials like TiO2 enjoy very high throughput rates with original Floveyor machinery and at a much lower capital cost compared to other technologies.

- No dust emissions – An original Floveyor does not require expensive extraction or filtration systems, which reduces costs while improving safety.

- Minimal residue – There’s little or no powder residue left in the machine, even after a full batch transfer. This means your workforce has limited, if any, exposure to hazardous powders, even during cleaning.

- Fast and easy cleaning – With other powder handling conveyors, cleaning is labour-intensive. For example, cleaning bucket feeders, screw feeders, or flexible screw feeders requires operators to dismantle the equipment. To thoroughly clean a bucket elevator, it can take four people an entire day to clean the machinery because all the coverings needs to be removed to get inside the machine.

- Operator safety maximised – An original Floveyor can be dry cleaned or wet washed, further reducing the exposure of operators to the materials being handled.

- Factory acceptance testing available – Floveyor provides factory acceptance testing prior to purchasing, so you can assess the suitability of the equipment.

How we can help

If you’re ready to futureproof your materials handling, get in touch with us to find out how original Floveyor machinery and equipment can help deliver safe, rapid conveying of high-risk materials. We’re ready to help you find the best conveying solution for your plant and will work with you to ensure the conveying solution you choose today will be the workhorse for your bulk materials handling for years to come.