Can an industrial conveying system shine in a hospitality venue? That’s what Gage Roads Brew Co wanted when designing their first brewpub in the port city of Fremantle, Western Australia (WA). The brewery sits front and centre in their waterfront restaurant and bar.

Gage Roads was searching for a high-quality conveyance system that not only possessed industrial-grade performance but also blended seamlessly with the aesthetics of the brewpub, which had swiftly gained popularity among both tourists and locals.

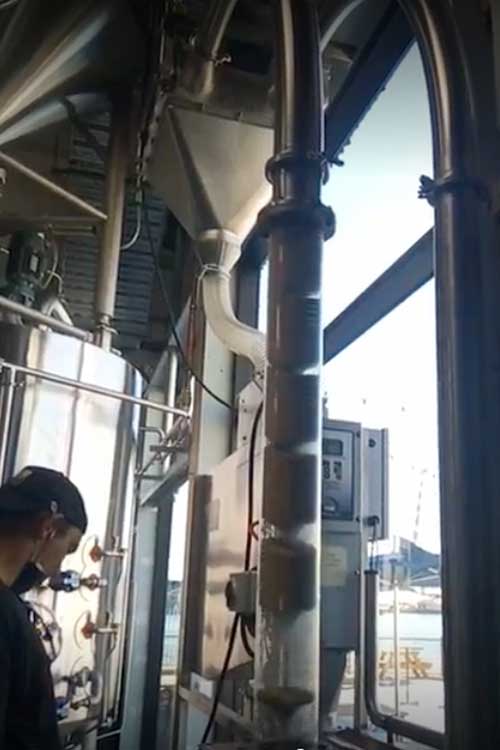

Tasked with designing a technology-forward venue for craft brewing, Project Engineer Peter Carpenter prioritised adjusting the transfer speed to accommodate multiple discharge points and showcasing the movement of grains through the tubes.

“We wanted to achieve 2,000 kilograms per hour of grain to the mill and we needed the ability to add specialty grains into the transport from within the building,” Peter said. “We wanted to have inspection points where the grain and rope system could be seen.”

Peter had an additional – and unusual – challenge for the new plant. “Function and reliability are the most important; however, appearance also has a significant impact on the venue’s success.”

Gage Roads explored other conveying systems but weren’t satisfied with their options. It meant they would need to purchase one conveying system to transfer grain and another that matched their brewery’s sleek, contemporary design.

“A second conveying system would add clutter, increase cleaning time, and look unsightly,” Peter said. “It wasn’t the image we wanted to portray at our new hospitality venue.”

Gage Roads, with a preference for collaborating with local businesses, seized the opportunity when they discovered that Floveyor’s powder handling solution featured tubular drag conveyors (TDC) capable of efficiently distributing bulk materials to multiple discharge points. In response to Floveyor’s invitation, they promptly visited the company’s headquarters in Perth.

Floveyor, the pioneers of the aero-mechanical method of conveying (AMC) and FloDisc® technology, have been manufacturing conveyors and process line technology for more than 60 years. They engineer each powder handling solution to meet the unique materials handling challenges and plant design requirements for their customers.

Their AMC technology is designed for gentle but rapid transfer of materials, while their TDCs are engineered to move powder and granules at controlled speed, which allows for more complex process line routes and multiple discharge points. It was determined a TDC was the best fit for what Gage Roads needed.

Gage Roads was confident the company had the experience and engineering talent to create a custom machine for food and beverage applications and meet their deadline for opening the venue.

“There are risks involved in taking on new technology, but Floveyor had well-established conveying systems already,” Peter said. “Floveyor demonstrated success in grain conveying from the throughput of their operation and with a number of client references. The partnership for developing and showcasing this technology was too good for us to pass up.”

Floveyor’s long-term investment in machine design and quality materials suited the Gage Roads project. Polished stainless steel tubing is standard for Floveyor conveyors.

Ease of maintenance and control were a crucial factor in Gage Roads’ decision to invest in Floveyor technology. To enhance the customer experience for the brewery, Floveyor engineered special features for its tubular drag conveying system.

“Floveyor designed the system from drawings provided by Gage Roads. The system had to run from the outdoor silo through the building to the mill,” Peter said.

The conveying system that met Gage Roads’ specifications was manufactured by Floveyor in their Perth factory.

“The stainless steel tubing and component parts were in keeping with the rest of our venue,” Peter said. “Clear tubing enables patrons and visitors to watch grain transport and give them a better understanding of the beer-making process.”

Floveyor delivered the new conveying system to the Gage Roads venue and oversaw the installation. Training was provided onsite for both operations and maintenance.

“The installation went very smoothly,” Peter said. “The Floveyor started up straightaway and soon bedded into our process. It has worked well for us.”

Gage Roads Brew Co chose Floveyor’s tubular drag conveying system for its compact size, grain transfer display, easy cleaning and maintenance options.

For more information

If you need conveying machinery and process line technology for your hospitality venue, Floveyor is a good choice for both function and form. Contact us to learn more.