Urea is a versatile material with wildly divergent applications. Formed from a synthesis of ammonia and carbon dioxide this nitrogen rich chemical compound is the major component in 90% of the world’s agricultural fertilisers. It’s among the most effective moisturising ingredients in skin creams and is a key ingredient in industrial products such as resins and glues.

Global urea production is expected to exceed 202 million tonnes in 2016. Since 2012 China has accounted for over 40% of urea production and is the fastest growing market along with India, the Middle East.

A challenging material….

Solid urea is marketed mainly in prill or granular forms. As a solid, urea is hygroscopic, abrasive and heat sensitive. Prills made from solidified droplets of molten urea are surprisingly fragile.

Dust control is vital as urea dust is a potentially hazardous source of soft tissue damage and eye irritation.

…meets a complete conveying solution

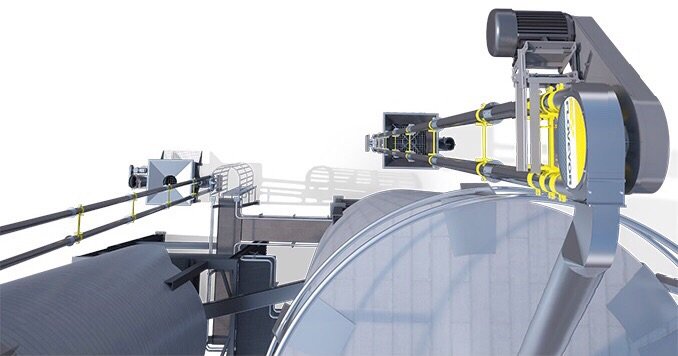

A safe, swift, F5 Floveyor moves up to 87,000kgs of urea prills per hour at any inclination.

However, we offer a range of highly adaptable conveyors suitable for applications requiring varying throughputs.

Besides being matchlessly fast, the Floveyor is robust, efficient, heat neutral and gentle. It conveys undamaged urea prills smoothly at virtually any angle, over distances of up to 20 metres.

Furthermore, Floveyors are exceptionally easy to operate and their simple modular design and small footprint make for effortless integration and maintenance.

Measured against all our industry standards for safety, speed and durability, a Floveyor is arguably the lowest cost per unit method of elevating urea.

Safety first – operate dust free

Contact with urea dust is a recognised health hazard. Personal Protective Equipment is essential to guard against skin and eye contact or ingestion through breathing or swallowing dust.

Where traditional open bucket and belt conveyors expose operators to urea dust, an enclosed, filter free aero-mechanical Floveyor operates dust free. This protects the integrity of the production environment and minimises hygroscopic build-up.

Speed second – operate cake free

In addition to providing a safe clean workplace, choosing the equipment best suited to managing urea’s hygroscopic qualities will save time and money.

A number of factors determine how much moisture urea will absorb during processing. These include particle shape and size, and varying chemical composition and purity levels. External factors including climatic humidity and how urea is stored and for how long also play a big part. Whatever the reasons, the costs of clearing adhesive lumps of caked urea from clogged conveyors can be substantial.

Urea crystals formed when moisture absorbent dust particles or fines dry out can clog and damage many traditional conveying systems.

Crystallised urea is extremely difficult to remove from extraction filters, which can also be expensive and time consuming to replace.

Floveyors operate filter free at speeds of up to 7m/sec using fluidising aero-mechanical technology. This keeps urea prills at ambient temperature and delivers them intact. Minimal atmospheric exposure all but eliminates problems caused by moisture absorption and caking.

Integrating the additional equipment needed to control dusting and crystallisation can add significantly to the cost and complexity of conveying urea.

Pneumatic blower systems generate heat. They require an integrated dryer to control condensation and prevent moisture absorbent urea crystals from coating and eventually blocking the conveyor. Vacuum pneumatic systems also need a dryer and filtered air at the infeed to control urea’s hygroscopic propensity. The complete wash down required to clean crystalline urea from a bucket conveyor can cause significant downtime.

Create the right conditions

Floveyor provides fully integrated, highly efficient preconditioning equipment to ensure the free flow of urea during processing.

We design and install custom fit preconditioning solutions for decanting urea from road, sea and rail transport or bulk bags. These include providing bag massagers on FIBC/bulk bag unloaders and inline lump breakers, to mesh and grids for manually removing product build up.

Our extensive range of value adding materials handling equipment means we can decant urea from sources as varied as 25-50kg manual bags, sea containers and tilt trucks. Floveyor’s consummately adaptable Floveyor can solve any logistical headaches linked to getting your raw urea materials into the plant. Once inline the Floveyor’s enclosed design and sealed system transfers urea point to point with zero hassles.

Completely cool under pressure

Overheating or rough handling can cause shell damage and breakage during bulk urea handling.

Our product contact parts are made from top quality stainless steel. This means that a Floveyor never raises a sweat. Better still, is highly resistant to urea’s corrosive nature.

Record turnaround times

A Floveyor can be configured to handle a plethora powdered and granular raw materials making it a complete conveying solution.

Flexible, uncomplicated design allows for rapid adjustments to the operating angle. Floveyors deliver total batch transfer leaving minimal residue and if needed our simple dry or wet cleaning regimes remove build up effortlessly.

Where urea is just one product in a complex and pressured production schedule, Floveyor will keep you on track.

Ask for what you want

Three generations of loyal conveying customers have trusted Floveyor to deliver simple ingenious solutions for handling bulk chemicals like urea. They asked us to build a tough, affordable, low maintenance aero-mechanical conveyor, so that’s exactly what we did.

Need more information on how fast a Floveyor can move urea? Just ask.

The following clients move urea with a speedy, efficient Floveyor.

|

|

|

|

|

|

|

|

|

|

|