The aero-mechanical conveyor: A comprehensive guide

What's in the guide

1. Introduction to aero-mechanical conveyors

The aero-mechanical conveyor (AMC) is a powder conveyor engineered and designed for bulk material handling of powders and granules. Aero-mechanical conveyor systems suspend and transfer bulk materials through fully enclosed tubes for the rapid, safe and gentle handling of bulk materials.

2. Understanding AMC

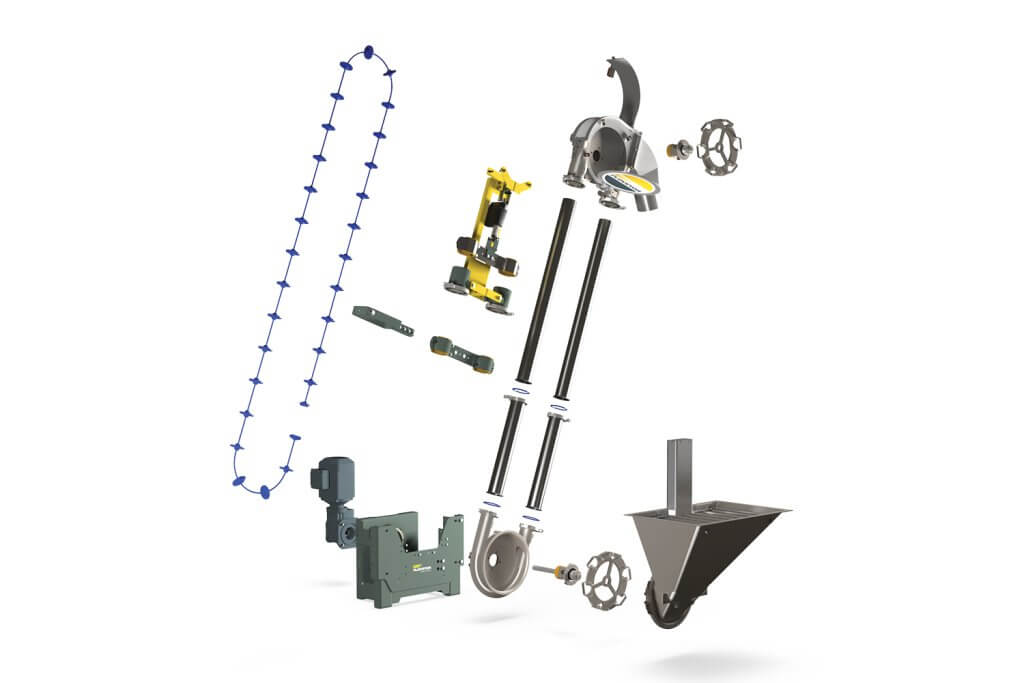

The sophisticated design of an aero-mechanical conveyor makes it a top performer in any process line or plant. At its most basic, an AMC comprises tubes, a rope, discs, air pockets and speed.

2.1 How an aero-mechanical conveyor works

A motor drives an internally circulating rope assembly at high speed in the conveying tubes. This creates a low-pressure air pocket behind each disc. Bulk material is fed into the system through a single inlet at the feed housing and accelerated into the conveying tubes by the rope assembly. Bulk material is suspended in the air pockets and drawn rapidly but gently to a single discharge point. Aero-mechanical conveyors with FloDisc® Technology have minimal to no material-on-material or material-on-equipment contact. It’s an ideal powder transfer system, even for materials with difficult properties.

Find out more about why FloDisc is essential to aero-mechanical conveying.

2.2 Core components of an aero-mechanical conveyor

- Tube: The main conveying tube is a closed-loop system that forms a continuous circuit for material movement.

- Discs: Polyurethane discs are moulded onto the rope at regular intervals. Discs can be manufactured using food-grade construction materials. Polymag discs are also available which have X-ray and metal detection capabilities and have improved resistance to chemicals.

- Rope Assembly: Discs are injection-moulded onto the rope assembly in a continuous loop running through the tube. Ropes are manufactured of galvanised steel or stainless steel and can be fully sleeved, along with the discs, to mitigate contamination risks.

- Inlet and outlet: Openings in the aero-mechanical conveyor system where material enters and exits the tube. They are designed to facilitate loading and unloading of bulk materials to and from the conveyor.

- Motor: The drive unit powers the movement of the rope assembly, propelling the discs and material through the conveyor system. It is essential for controlling the speed and direction of material flow.

- Tensioning system: A tensioning system maintains proper tension in the rope to ensure smooth operation of the conveyor. Too much slack or excessive tightness affects performance and can damage the AMC over time.

3. Advantages of using an aero-mechanical conveyor

Aero-mechanical conveyors offer a superior powder conveying system compared to other methods of powder handling. Aero-mechanical conveyors are a popular choice for industries that require efficient and gentle handling of materials with minimal risk of contamination or degradation. When choosing a bulk materials handling conveyor system, consider these key benefits of using aero-mechanical conveyors:

- Gentle material handling: Aero-mechanical conveyors reduce the risk of degradation or damage to bulk materials. This is particularly important for fragile materials or products that require careful handling.

- High throughputs: An aero-mechanical conveyor can rapidly but safely transfer powders and granules for even the most hazardous materials. Throughput can reach up to 150,000 kph (115.7 US tph).

- Versatility: AMCs handle a wide range of materials, including powders, granules, pellets, flakes, seeds, beads and nuts. A single machine can elevate thousands of different materials, mixes and blends. This makes them suitable for a wide range of industrial and food and beverage applications.

- Efficiency in conveying: You can efficiently transport materials at any elevation. This helps in optimising the layout of the production facility and streamlining material flow.

- Fully enclosed design: The enclosed design of AMCs prevents contamination of your bulk materials. This is crucial for industries where hygiene is paramount, like food and pharmaceutical manufacturing. The benefits of a fully enclosed design extend to dusty and explosive materials. It’s a key component of keeping workers safe.

- Low maintenance: Because aero-mechanical conveyors have been engineered with fewer moving parts compared to other conveyor systems, the machinery experiences fewer problems. Regular inspections and basic maintenance ensure maximum uptime and availability.

- Total batch transfers: Minimal product wastage is experienced with AMCs due to little or no residue between batches. Total batch transfers also reduce cleaning time which can make a significant impact on production and operator efficiency.

- Energy efficiency: The aero-mechanical conveyor provides highly efficient conveying, unprecedented availability, and eco-efficiency with minimum energy consumption. AMCs are known for low operating costs.

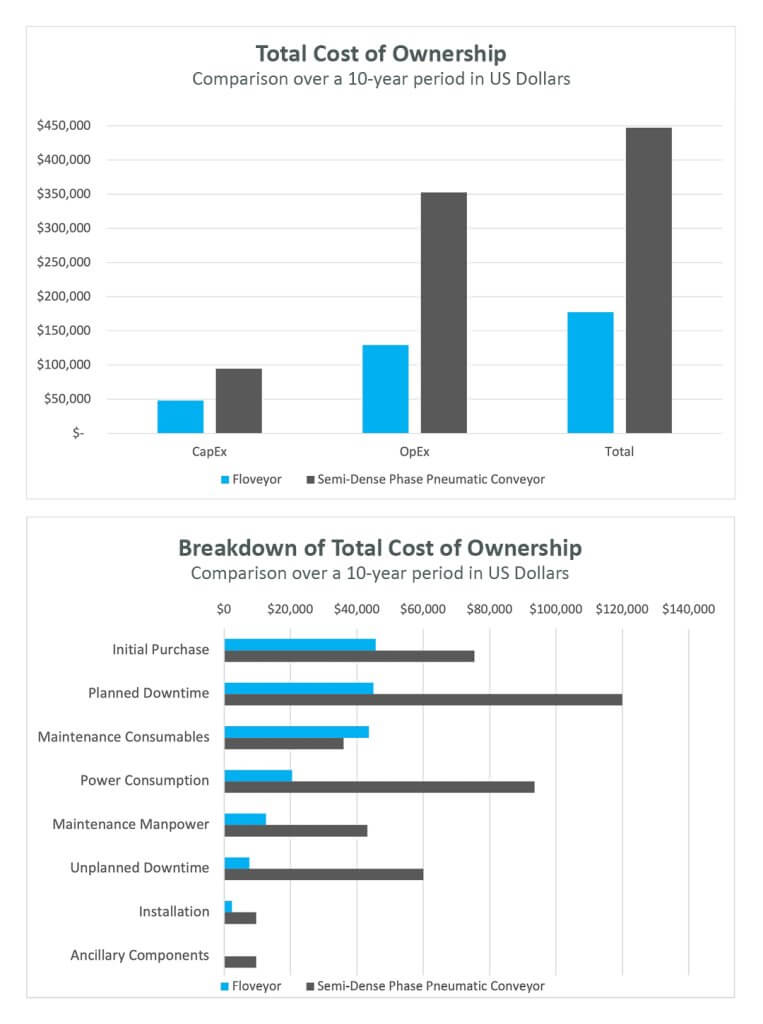

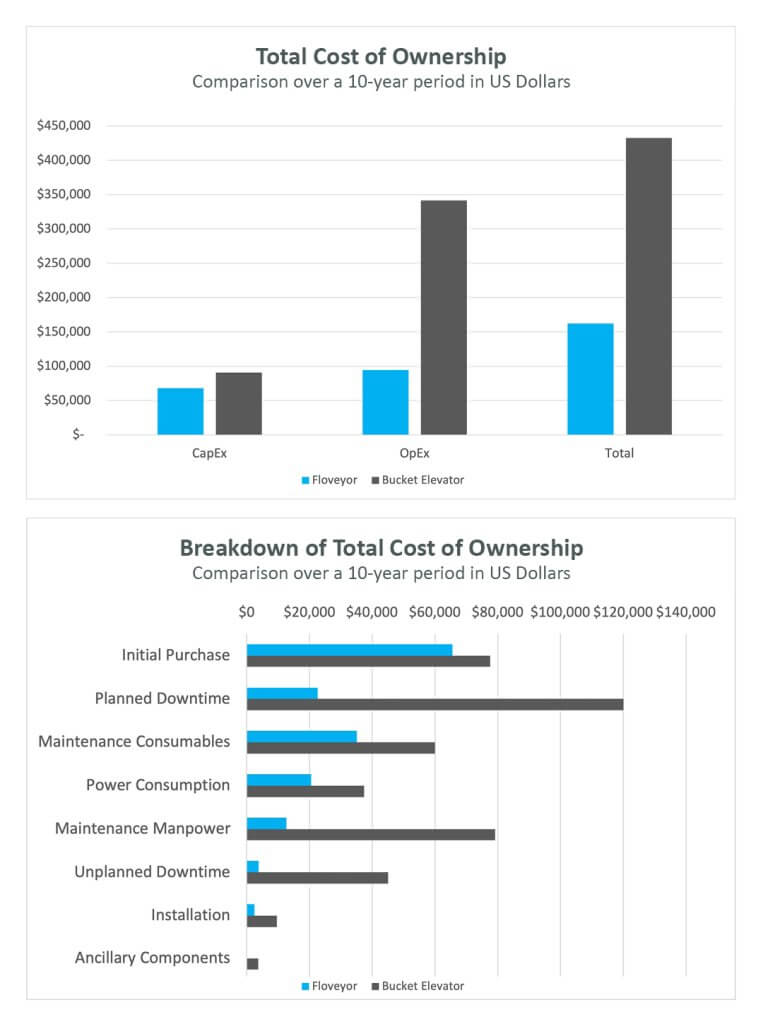

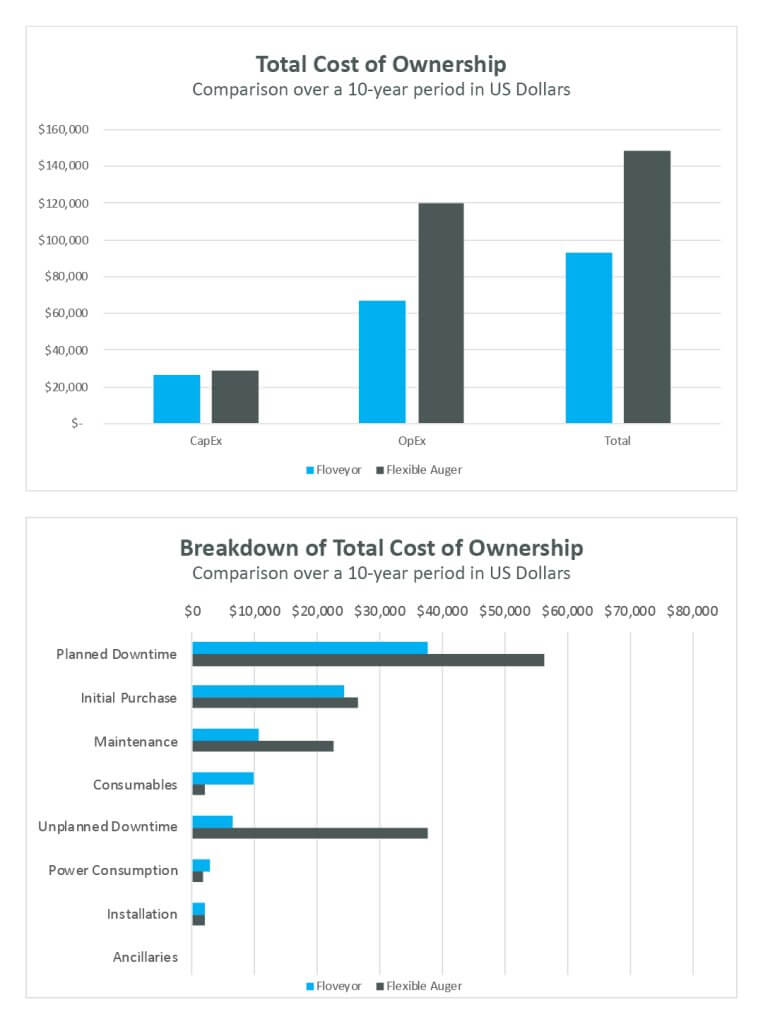

- Low total cost of ownership: When you factor in energy-efficient, high availability, low maintenance and cleaning requirements; high reliability; and long-term durability, a Floveyor AMC is often the most cost-effective powder conveyor over time.

4. Common applications and industries for an aero-mechanical powder conveyor

The AMC is a perfect powder conveyor that can handle thousands of materials. It is ideal for free-flowing materials but will also easily manage materials that tend to stick, clump or are prone to separation. Due to its gentle handling, an aero-mechanical conveyor is a good choice for mixes, blends and fragile materials. AMCs are used for both industrial applications and for food and beverage production.

- Industrial materials, including activated carbon, potash, clay, nickel powder, nylon powder, cement, perlite, cat litter, sandalwood chips, sawdust, soap powder, urea prill, cellulose powder, plastic beads, Ti02, grout mix, resin powder mixes, lithium hydroxide, gunpowder, silica, bentonite, carbon black, melamine.

- Food and beverage materials, including sugar, icing sugar, egg powder, milk powder, flour, lentils, muesli, salt, green tea, instant coffee, coffee beans, tea leaves, lactose, malt, rice, nuts, grain husk, livestock feed, animal nutrition, pet food, kibble mix, seed mix.

The industries most likely to use an aero-mechanical conveyor include:

- Food and beverage

- Manufacturing

- Agriculture

- Chemical processing

- Mining and resources

- Critical minerals.

5. Selecting the right powder conveyor for your application

AMCs can be customised to suit any plant. They have a small footprint and come in mobile units so they work equally well in greenfield and brownfield plants. Working with a powder handling specialist is the best way to ensure your aero-mechanical conveying system is ideally suited to your operation.

5.1 Considerations for material selection

An AMC can transfer thousands of bulk materials, but it’s a good idea to ensure your materials are compatible with aero-mechanical conveying. Large lumps can damage the AMC and should be broken up before conveying. Foreign bodies in the materials can potentially damage the conveyor. This can include things like sacks, knives, tools and fasteners.

Here are things you need to consider about specific material properties.

Abrasive materials

An AMC with FloDisc is ideal for conveying abrasive materials like salt, sand, sugar, cement or limestone. Care needs to be taken with highly abrasive materials, and AMCs are generally not advised unless it’s for light-duty applications, at lower throughputs, and with reduced operational hours. Heavy-duty operation using highly abrasive materials causes rapid wear on components, which leads to high ongoing costs.

Particle size

The larger the tube on an aero-mechanical conveyor, the larger the particles it can handle.

- 3-inch/76mm tubes – up to 0.25in/6mm

- 4-inch/102mm tubes – up to 0.35in/9mm

- 5-inch/127mm tubes – up to 0.48in/12mm.

Moisture content

Moisture can be problematic for AMCs. Low levels of moisture work best to ensure there’s minimal build-up in the conveyor. A normal application range would be 0% to 6% moisture content.

Medium levels of moisture can result in clumping, bridging in hoppers and increased internal build-up. When this happens, cleaning requirements need to be assessed. Moisture levels of 7% to 15% are considered to be in the medium-level range.

Materials with high moisture content are not suitable for aero-mechanical conveyor systems. Most powders with high moisture levels will turn into a slurry during handling and continually build up inside the conveyor. Some materials like grains can become more abrasive with increased moisture. Moisture levels of 16% and higher are not recommended.

Watch for stickiness and smearing as signs of high moisture levels.

Hygroscopic and deliquescent materials

High humidity can affect the flow of materials susceptible to moisture. It’s recommended highly hygroscopic materials are processed in a controlled, dehumidified environment for best results. Rigorous inspections and cleaning regimes are recommended whenever shapeshifting materials are being transferred.

Oily and waxy materials

Diligence around cleaning and preventative inspections are essential when handling oily and waxy materials. The materials often smear on internals and chutes during transfer. Build-up can block and stall the powder conveyor, which can be extremely difficult and time-consuming.

Fragile materials

Friable and fragile materials are handled very successfully with an aero-mechanical conveyor, with no reduction in the integrity of the particle. For larger particles, rubber-lined chutes, spiral discharges to stop freefall impact, and flow-controlled infeeds greatly reduce particle damage.

Hazardous and explosive materials

The AMC is a good choice for materials that can catch fire, like gunpowder or sugar. The fully enclosed, dust-free system allows for safe, rapid transfer of difficult materials. A conveyor can be manufactured with a variety of construction materials and contact surfaces to ensure ultimate safety and hygiene while conveying.

Blended mixes

An aero-mechanical conveyor with FloDisc Technology preserves blend and mix integrity by suspending materials in air pockets and transferring them as a blended unit. The product will not separate during handling and the product will be discharged in the same ratio as it was fed into the machine.

Temperature extremes

A normal range of temperatures for a powder transfer system using an AMC is 10C/50F to 70C/158F. Temperatures lower than this can lead to freezing and internal blocking, especially if moisture is present. Higher temperatures require upgrades for safe materials handling. Temperatures above 130C/266F are not recommended.

5.2 Layout and throughput considerations

An aero-mechanical conveyor has the capacity for high throughputs, which are dependent on the size of the machine and the materials being handled. As a rule of thumb, the following throughputs are achievable:

- 3-inch/76mm tubes: 33 US tph/100 – 30,000 kph

- 4-inch/102mm tubes: up to 66.1 US tph/60,000 kph

- 5-inch/127mm tubes: up to 115.7 US tph/105,000 kph.

The AMC adapts seamlessly to any location or process. Their flanged, modular design makes them a perfect powder conveyor for self-managed installations. The aero-mechanical conveyor is well suited to lengths of up to 20 m (65 ft). AMCs have a small footprint and can operate in tight spaces. They also come as standalone mobile units, which makes them particularly well-suited to small plants.

Aero-mechanical conveyors work best in straight-line installations, including those with 90° corners to accommodate vertical and horizontal transfer for bulk powder handling. AMCs can also support bi-directional conveying, if required.

6. Safety and environmental considerations

An aero-mechanical conveyor system is a safe, energy-efficient option for bulk material handling of powders and granules. The fully enclosed system creates a dust-free operation which improves worker health and wellbeing. Quiet operation also contributes to a safe working environment. For hazardous material handling, conveyors can be ordered so they’re compliant with ATEX and IECEx codes.

Energy-efficient powder conveyor

The Floveyor AMC is extremely energy-efficient, especially when compared to other conveying technologies like pneumatic conveyors. Energy efficiency contributes to lower operating costs and lower total cost of ownership.

An aero-mechanical conveyor is a far more energy efficient powder conveyor than a pneumatic conveyor.

Cleaning an AMC

Easy cleaning options with both dry and wet wash downs saves water and energy costs. Compared to conveying technologies like bucket elevators, a Floveyor AMC is quick and easy to clean and requires no tools for access.

Floveyor aero-mechanical conveyors can be Clean In-Place (CIP) or Clean Out-of-Place (COP) and come with three cleaning options:

- Dry cleaning – an AMC can be cleaned with air or inert gas to return any settled residue to the main product stream.

- Inert purging – Inert materials such as granular salt or broken rice can be used to clean the aero-mechanical conveyor and flush out residue. For example, a bakery may use flour to purge the additive residue of a previous run and ensure there’s no wastage in the recipe.

- Wet cleaning – A Floveyor AMC can convey liquids at high speeds for a recirculating wash cycle to clean the conveyor internals.

7. Maintenance and durability

Aero-mechanical conveyors require minimal maintenance. Regular, preventative maintenance eliminates costly, unplanned downtime during production. The manufacturer will recommend inspection and adjustment intervals for:

- Rope assembly

- Sprocket assemblies

- High-speed bearings

- High-speed seals

- Internal housing surfaces

- Fastener tightness

- Other seals.

Maintenance intervals vary depending on application, materials handled and hours of operation. The Floveyor AMC provides quick access to areas requiring frequent cleaning, inspection or maintenance.

When compared to a bucket elevator, an aero-mechanical conveyor requires significantly less maintenance man-hours.

When well-maintained, Floveyor AMCs can operate up to 24 hours per day. A rope assembly will last 3,000–5,000 hours of operation when the conveyor has been installed and operated correctly. It’s normal for a Floveyor AMC to operate for decades with minimal downtime and high availability rates.

See how a Floveyor aero-mechanical conveyor outperforms a flexible auger when it comes to downtime.

8. Custom solutions and configurations

Bulk material handling equipment is available to complement the aero-mechanical conveyor, including:

- Tubular drag conveyors

- Mobile systems

- Transit loading

- Reusable FIBC unloader

- Disposable FIBC unloader

- FIBC unloading screwfeeder

- AMC screwfeeder

- Trough screwfeeder

- Dosing screwfeeder

- Rotary lump breaker.

As the original inventor of aero-mechanical conveying, Floveyor has extensive experience custom-designing powder handling systems to complement the AMC. This entails:

- Discovery and solution modelling

- Applying expertise to guide concept through to reality

- Global support

- Reliable, after-sales support.

8.1 Floveyor powder handling specialists

Custom solutions may include application-specific chutes, hoppers and transfers to integrate standard Floveyor AMCs and powder handling equipment with existing plant or third-party supplied components.

If a fully customised solution is required, Floveyor can design and build structural, mechanical and electrical solutions to meet your exact requirements.

9. Disadvantages / key challenges in AMC system design

The aero-mechanical conveyor is not the best choice for every application:

- Lengths more than 30m/100ft where a single run is more economical

- Moisture content above 20% w/w

- Waxy, fatty, sticky or oily materials

- Materials that bind under compressive loads.

A tubular drag conveyor can be a better choice for:

- Complex routes with multiple corners and/or bends

- Multiple planes

- Multiple inlets and/or discharge points.

Conclusion

An aero-mechanical conveyor is the workhorse of powder conveying systems all over the world. Its versatility, durability and low total cost of ownership make it an attractive option for myriad industrial applications and food and beverage manufacturing operations. When you consider its ability to rapidly transfer thousands of materials safely and gently with a single machine, an AMC is the best choice for powder handling.

Floveyor invented aero-mechanical conveying in 1958 in Perth, Western Australia, and continues to evolve powder conveying equipment. As powder handling specialists, we can help you discover the best powder conveyor for your plant, to ensure your performance expectations are being met.

Our materials matcher will help you discover the best AMC for your operation.

Get in touch with Floveyor for advice on powder handling and learn how to optimise your operation for maximum yields and profit.