Choosing the right bulk materials handling conveyor system

What's in the guide

Your conveyor system is a key contributor to the success and profitability of your plant. Increasingly, there’s more choice for engineers and integrators to optimise their powder and granules handling. With choice comes opportunity – and risk.

Because material properties and operational demands influence the efficacy of each conveying system, there’s no one-size-fits-all solution. Balancing the needs for efficiency, safety and cost – while considering process line complexity and future growth – is the key to making the right decision about the conveyor you use for bulk material handling.

So what should you consider when choosing a bulk material handling equipment for powders and granules? How do you know if you should use a belt conveyor, a screw conveyor, or a drag chain conveyor? Is a pneumatic conveyor positioned to support your plant better than a bucket elevator? How does an aero mechanical conveyor stack up against a flexible auger conveyor? This guide was developed to help you answer those questions and make an informed decision about the different types of conveyors used for modern powder and granules handling.

1. Understand your material

1.1 Material characteristics

Powders and granules come in a variety of sizes and characteristics. Whether your material flows freely, tends to stick, or is prone to separation, understanding the inherent traits of your bulk materials paves the way for successful conveying.

Size matters

The size of the particles in your material dictates the conveyor’s speed, capacity, and even the type of machinery you use. For example, fine particles easily become airborne or fluidise, posing different challenges than particles prone to clumping. Larger granules, like nuts or beads, may require systems to handle their weight and reduce breakage.

Beyond basic traits

So what kind of challenges do plants face when conveying powders and granules?

- Abrasive materials: Operations handling abrasive materials may experience rapid wear on components, leading to high ongoing costs. Look for conveyors resistant to degradation to ensure longevity and reduce maintenance costs.

- Fluid and free-flowing materials: These materials can swiftly move, sometimes leading to overflow or speed-related challenges. Accurate speed controls and barriers might be necessary.

- Hygroscopic materials: Environmental conditions influence the handling of hygroscopic powders. High humidity affects flow characteristics, which increase internal build-up. Cleanability becomes an important factor if you’re transferring hygroscopic materials.

- Cohesive materials: Sticking and clumping of materials can cause blockages or inconsistent flow. You can ensure consistent movement of your bulk materials with vibration or agitation features in your conveying system.

- Fragile materials: When handling friable materials, conveyor integration, layout and design of infeed and discharge chutes are often overlooked as the largest contributor to damaged particles. Rubber-lined chutes, spiral discharges to the bottom of the hopper to stop freefall impact, and flow-controlled infeeds all greatly reduce particle damage.

- Hazardous dusts: If the material has potentially hazardous or toxic dust, containment becomes crucial. This protects both the environment and the health of workers. Look for filters and dust extraction technology.

- Moisture content: Even when dealing with dry materials, some moisture might still be present. Materials with higher moisture content can become sticky or clump together. Look for conveyor systems that give you the ability to condition these materials before they enter your process line.

- Potential agglomerates: If your material tends to form lumps or agglomerates, you’ll need a system that can break them down, ensuring a smooth conveying process.

- Blended mixes: Blends and mixes present unique challenges, especially when composed of varying densities, particle sizes, or handling characteristics. Ensure your product is discharged in the same ratio and blend integrity as it was fed into the machine

2. Define your operational requirements

2.1 Throughput volume

Every production process has a target for throughputs. Your conveyor system should match the transfer speed needed to achieve those targets. Before deciding on any conveyor, determine the volume of dry powder or granules you anticipate moving in a given time — hourly, daily, or weekly units. This helps in selecting a conveyor with the right capacity to avoid bottlenecks or under-utilisation. Consider potential growth in capacity targets and ensure the conveyor you select is able to meet those demands.

2.2 System layout

Every facility comes with a unique spatial blueprint. Some have ample horizontal space but limited vertical height, while others might be the exact opposite. Brownfield operations can experience more challenges in system layout, especially if the plant is old or is experiencing rapid growth. In that case, you’ll want to find a conveyor system that operates in tight spaces or has a mobile unit option.

Navigating spatial constraints

In spaces with limited horizontal leeway, vertical conveyors like the bucket elevator might be more apt. Conversely, sprawling spaces can benefit from longer, horizontal conveyors like tubular drag conveyors. It’s crucial to factor in other infrastructure like hoppers, silos, or machines the conveyor integrates with.

Vertical vs. horizontal movement

Transporting materials along a horizontal route often presents a broader array of conveying options. With fewer gravitational constraints to consider, many conveyor types can efficiently handle the task, depending on the distance and throughput.

On the other hand, vertical conveying presents unique challenges. Elevating materials, especially at high throughputs, narrows down the list of suitable conveyor options.

3. Environmental and safety considerations

Overlooking environmental and safety considerations can lead to dire consequences in your bulk material powder handling operation, both in terms of worker safety and operational expenditure. Companies are increasingly focused on ESG, so your plant’s environmental impact is likely to come under scrutiny if it hasn’t already. Proactively addressing these factors ensures a safe working environment, contributes to operational efficiency, and supports regulatory compliance.

3.1 Dust and emissions control in conveyor systems

Given the nature of powders and granules, dust and emissions are inevitable adversaries. With foresight and strategic planning, their adverse impacts can be curtailed.

Strategies for minimising environmental impact

Introducing effective dust collection and air filtration systems reduces airborne particles. These systems ensure cleaner air discharge, meeting environmental standards and reducing potential external contamination.

The imperative of system sealing

A well-sealed conveyor system minimises the escape of powders or granules during material transfer, preventing wastage and environmental contamination. Seals, gaskets, and skirting are vital components in ensuring containment. Regular inspections and maintenance are essential to ensure seals have not been compromised, which can occur through normal wear and tear.

3.2 Worker safety

Prioritising worker safety isn’t just a moral obligation—it’s also a sound business strategy.

Ensuring operational safety

Incorporating features like emergency stop mechanisms, handrails, safety guards, and interlock systems prevent potential accidents. Additionally, clear signage on all machinery and equipment in your conveying system keeps operators informed and vigilant about operational procedures and potential hazards.

Access and upkeep

Easy access to the conveyor system for maintenance and inspections can significantly reduce downtime and improve overall system health. If the materials being conveyed pose a health risk, it’s crucial to limit operator exposure. This can be achieved through enclosed systems, personal protection equipment (PPE), and ensuring your workforce receives proper training on handling such materials.

3.3 Hazardous zoning

Dry powders, especially organic ones, can pose explosion risks, turning seemingly benign operations into potential hazards.

Defining explosion risks

Before choosing a conveyor system, it’s essential to conduct a thorough risk assessment to define any dust explosion hazards. Recognising the materials’ Minimum Ignition Energy (MIE), amongst other combustible limits and the presence of any ignition sources are pivotal in this analysis.

Compliance with ATEX or IECEx standards

If there are inherent risks of explosion, compliance with globally recognised standards such as ATEX (in Europe) or IECEx (internationally) is non-negotiable. These standards provide guidelines on equipment and protective systems intended for use in potentially explosive atmospheres. Ensuring your conveyor system adheres to these standards not only guarantees safety but also reinforces trust with stakeholders.

3.4 ESG compliance

Environmental, social, and governance (ESG) initiatives are fast becoming a standard in business. Manufacturers are being asked for more transparency in how they impact the environment and about their consumption of natural resources. Ensure the OEM of your conveying system contributes to your ESG maturity and supports your supply chain ESG/sustainability goals.

4. Conveyor system technologies and suitability

When it comes to bulk materials handling of powders and granules, one size certainly does not fit all. Different conveyor technologies come with distinct advantages, limitations, and best-use scenarios. Understanding the nuances of different conveying technology allows you to navigate towards the best fit for your specific application.

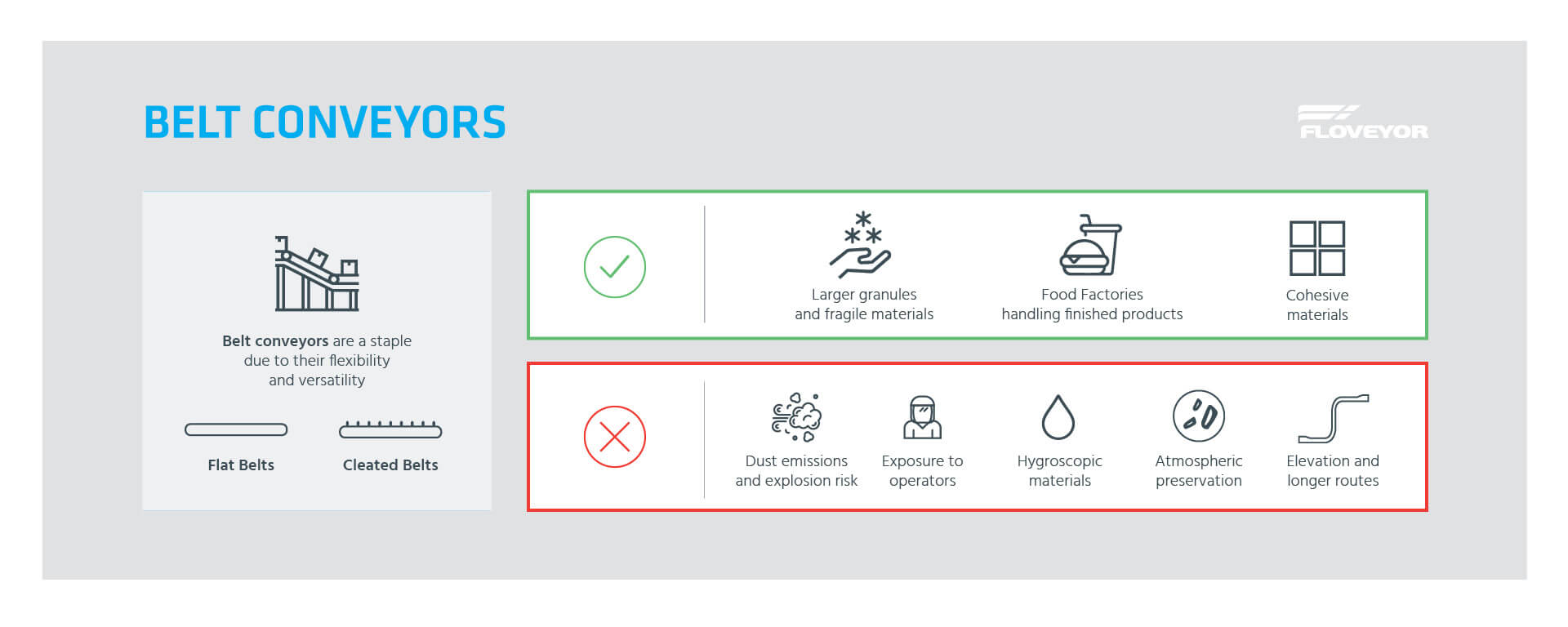

4.1 Belt Conveyors

The belt conveyor is a staple in many industries due to its simplicity and versatility. There are two main types of belt conveyors.

Types: Flat or Cleated

- Flat Belts offer a smooth surface for material transport. They can be paired with various accessories, like scrapers, to handle specific materials.

- Cleated Belts come with raised sections, or cleats, which help keep the material on industrial belt conveyors. Cleated belts are especially beneficial for inclines or specific material characteristics, like round objects that might easily roll during transfer.

Best for:

- Larger granules, flakes, fragile shapes: The continuous surface of the conveyor belt ensures minimal breakage and degradation of these types of materials.

- Food factories handling finished products: The belt conveyor is often preferred in food processing units, especially for larger food items, due to their gentle handling of bulk materials.

- Cohesive, agglomerating materials: Flat belts, when fitted with scrapers, can effectively handle materials that tend to stick or clump together.

Concerns:

- Dust emissions: Open design limits conveyor belt uses, making them prone to dust emissions, especially when transporting fine powders.

- Exposure to operators: Due to the open design of belt conveyors, materials being transported are accessible, making this type of conveyor unsuitable for hazardous materials which can pose health risks.

- Hygroscopic materials: Belt conveyors aren’t ideal for materials that absorb moisture unless they’re used in a controlled environment.

- Dust explosion risks: Given the exposure levels, materials prone to dust explosions aren’t recommended for belt conveyors.

- Preservation from atmosphere: For materials sensitive to external environmental factors, like humidity, a conveyor belt system might not offer the desired protection.

- Material elevation and longer routes: The design of belt conveyors limits their ability for elevating materials vertically or navigating longer, complex routes.

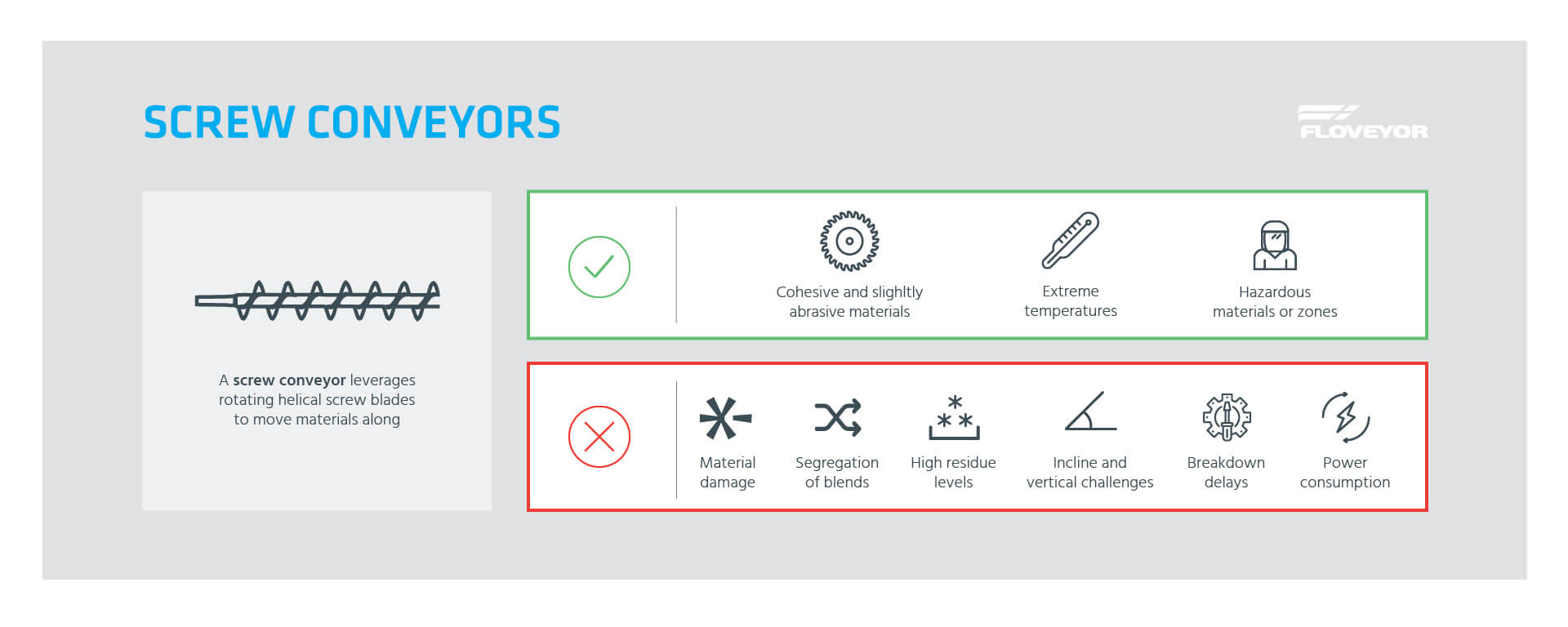

4.2 Screw Conveyors

A screw conveyor, also known as a screw auger conveyor, leverages rotating helical screw blades to move materials along. Screw conveyors are compact, efficient, and highly versatile. Fully enclosed vertical screw conveyors are often used to convey materials vertically before gravity feeding into one or more silos or hoppers. Screw conveyors are relatively heavy yet can be supported from the ground, requiring minimal elevated supports.

Routes: Horizontal or slight inclines

While predominantly used for horizontal transport, screw conveyors can also manage slight inclines, providing a degree of flexibility in routing.

Best for:

- Cohesive and slightly abrasive materials: The steady, uniform movement of a screw conveyor can efficiently handle materials that may stick or have minor abrasive qualities.

- Extreme material temperatures: Screw conveyors can handle materials at higher temperatures, given their design and the potential use of heat-resistant materials in construction.

- Hazardous materials or zones: An enclosed screw conveyor can safely handle materials that might be hazardous, as the containment minimises exposure risk.

Concerns:

- Material damage: The mechanical interaction with the rotating screw can lead to material degradation, especially if the material is fragile.

- Segregation of blends: Mixed materials might get separated due to differential movement, affecting the desired blend consistency.

- High levels of residue: Some materials might leave behind significant residues, affecting efficiency and necessitating regular cleaning.

- Steep incline and vertical challenges: While slight inclines are manageable, steeper ascents or vertical lifts can pose significant challenges, leading to blockages or inefficient transport.

- Breakdown delays: A malfunction or blockage can halt operations, sometimes for extended periods, affecting the production line’s overall efficiency.

- Power consumption: Consumption can be significant due to internal wall friction.

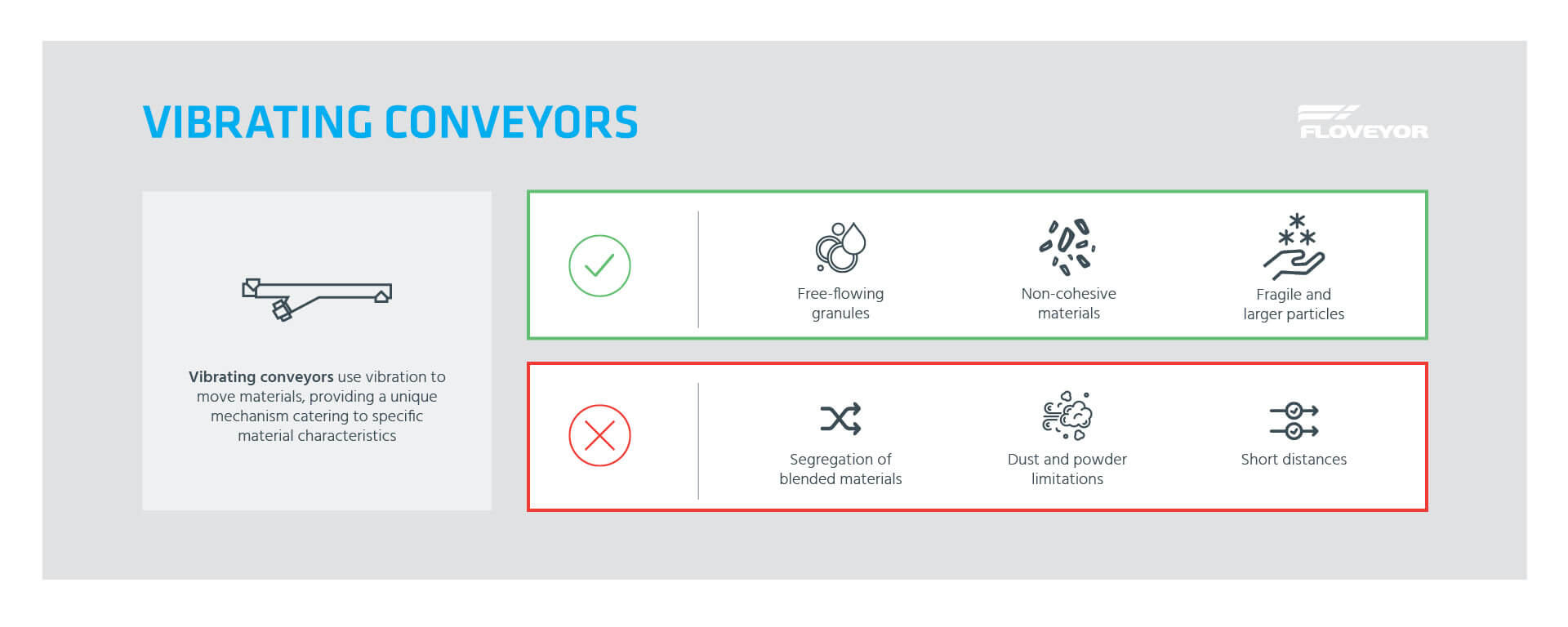

4.3 Vibrating Conveyors

Vibrating conveyors use vibration to move materials, providing a unique mechanism catering to specific material characteristics.

Routes: Horizontal movement

By design, vibrating conveyors are tailored for horizontal transport, making them ideal for linear routes without elevation changes.

Best for:

- Free-flowing granules: Vibration ensures granules move smoothly without sticking.

- Non-cohesive materials: Materials that don’t tend to clump or stick together are an excellent match for vibrating conveyors.

- Fragile and larger particles: Gentle vibratory movement ensures minimal breakage and degradation of larger or fragile materials.

Concerns:

- Segregation of blended materials: The vibratory motion might lead to differential movement, resulting in the separation of blended components.

- Dust and powder limitations: They’re not particularly suited for transporting fine powders, given the risk of dust emissions and inefficiencies in movement.

- Short-distance transfer: Vibrating conveyors are optimised for shorter distances, making them less suited for extended transport routes.

4.4 Drag Chain Conveyors

The drag chain conveyor, or drag conveyor, owing to its distinctive operating mechanism, provides a blend of reliability and adaptability for bulk material handling.

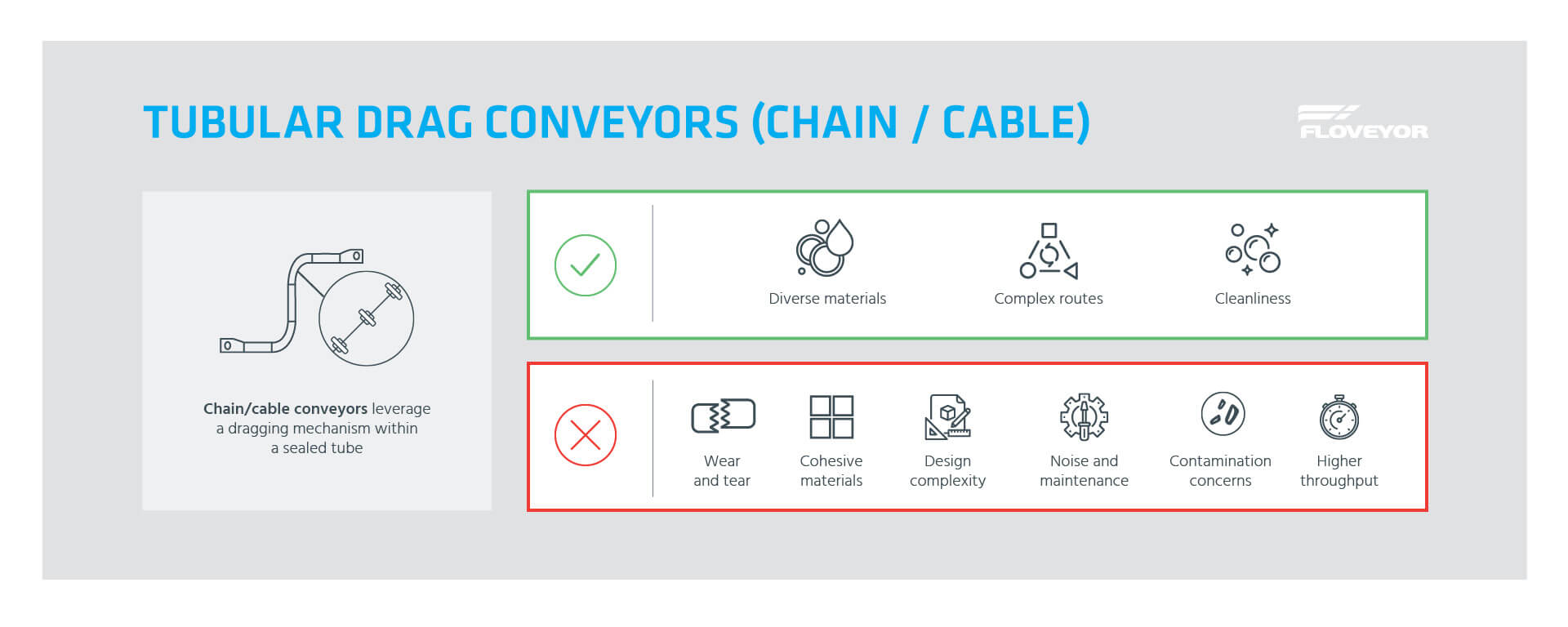

Tubular Drag Conveyors (Chain and Cable)

The tubular drag conveyor, either with chains or cables, leverage a dragging mechanism within a sealed tube.

Best for:

- Diverse materials: TDCs handle both powders and granules, even if these are abrasive or of high density.

- Complex routes: Thanks to their unique design, TDCs can negotiate intricate routes, including long horizontal and vertical runs, and manage radius corners adeptly.

- Cleanliness: Given their enclosed design, TDCs are an excellent choice for food products and the safe conveyance of hazardous materials, ensuring minimal or no contamination.

Concerns:

- Wear and tear: Despite their robustness, abrasive materials can accelerate wear, leading to increased maintenance needs.

- Handling cohesive or agglomerating materials: These types of materials might cause blockages or inefficient movement.

- Design complexity: Achieving the right conveying system design can be challenging, given the interplay of corners, verticality, throughput, and material characteristics.

- Noise and maintenance: TDCs, particularly the larger ones, can be noisy. In the case of breakdowns, especially with larger diameter chain conveyors, restoring operations can be challenging.

- Contamination concerns with chain conveyors: The wear from chain-on-chain interactions can introduce contaminants into the conveyed material.

- Size concerns for higher throughput: To manage greater throughput, larger diameter conveyors are needed, which can become cumbersome to support and maintain.

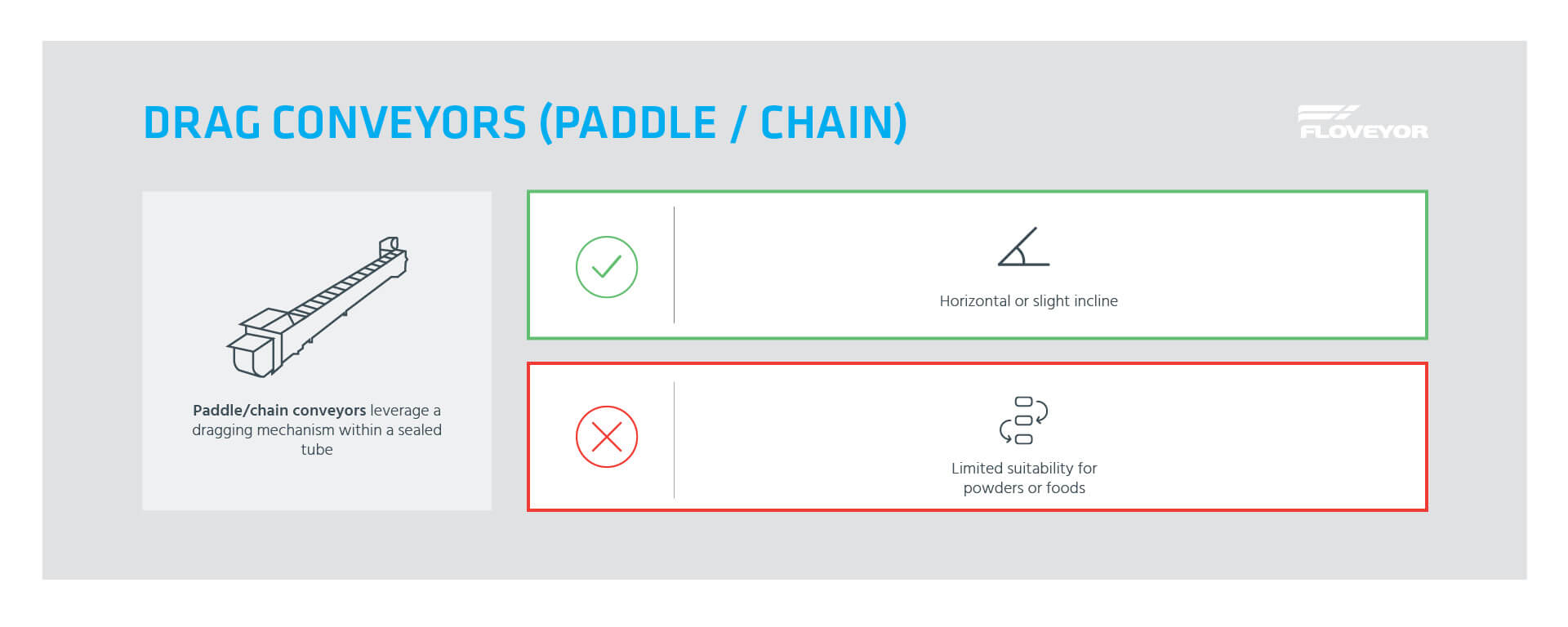

Paddle or Chain Conveyors

Primarily used for horizontal or slightly inclined transfer, paddle or chain conveyors use flat plates or paddles attached to a chain, to move the material along.

Best for:

- Horizontal or slight incline: Particularly adept at handling coarse or agricultural materials, a paddle or drag chain conveyor is not recommended for powders or foods.

Concerns:

- Limited suitability: They’re not recommended for transporting powders or foods due to potential contamination and inefficiencies in movement.

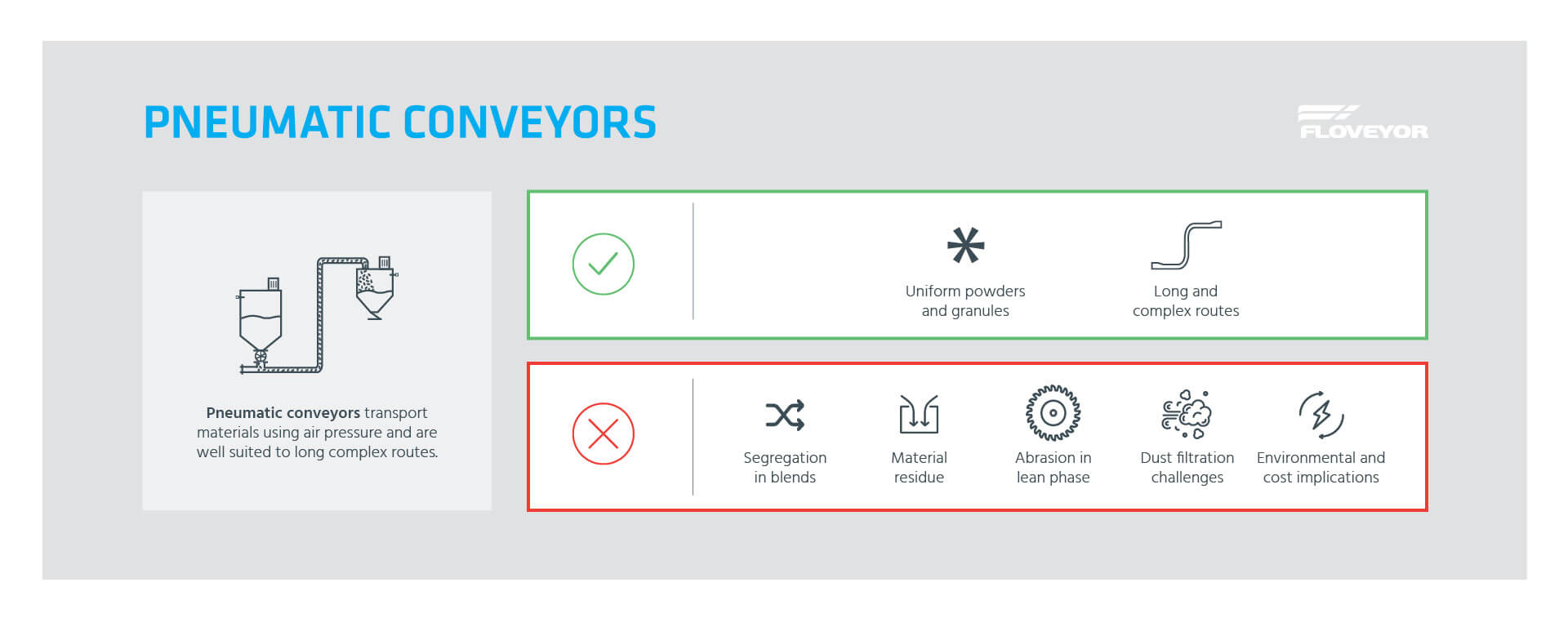

4.5 Pneumatic Conveyors

A pneumatic conveyor transports materials using air pressure. They are well suited to long, complex routes with minimal available headroom. Lean phase conveyors transport material at low pressure and high speed; dense phase conveyors transport material at high pressure and low speed. The type of conveyor selected depends strongly on the materials conveyed.

Vacuum Conveyors

Using negative pressure, these systems draw materials through the conveyor system. Due to the mechanics of creating a vacuum, these systems are typically used for shorter distances and may be more suitable for lower throughputs.

Blowing Conveyors

Leveraging positive pressure, materials are blown or pushed through the system. This methodology allows materials to be transported over longer distances, often in continuous manufacturing processes where larger volumes need to be moved over significant stretches.

Dense Phase Conveyors

Slow-moving, high-pressure systems are ideal for abrasive or fragile materials to minimise damage.

Semi-Dense Phase Conveyors

Balancing between dense and lean phases, Semi-Dense Phase Conveyors offer a middle ground in terms of speed and pressure for pneumatic conveying.

Dilute or Lean Phase Conveyors

High-speed, low-pressure systems are suitable for granular or non-abrasive materials.

Best for:

- Uniform powders and granules: Airflow ensures a consistent movement of homogenous materials, making pneumatic conveyors ideal for uniform powders and granules.

- Long and complex routes: Thanks to the fluidity provided by the air, a pneumatic conveyor can handle intricate routes, both horizontally and vertically, across considerable distances.

Concerns:

- Segregation in blended materials: The airflow can cause differential movement, potentially separating mixed components.

- Potential for material residue: Some materials, especially sticky or fine ones, might adhere to the conveyor walls, leading to residue build-up over time.

- Abrasion in lean phase conveyors: The high-speed movement in lean phase systems can cause abrasion, particularly when handling coarse or abrasive materials.

- Dust filtration challenges: Managing dust, especially with ultra-fine powders or materials with hygroscopic properties, can be challenging. Effective filtration is vital to prevent blockages or inefficiencies.

- Environmental and cost implications: The energy consumption of pneumatic systems, particularly at scale, can have significant environmental impacts. Additionally, both the capital and operational expenditures can be relatively high, making it essential to evaluate the ROI for your bulk material handler.

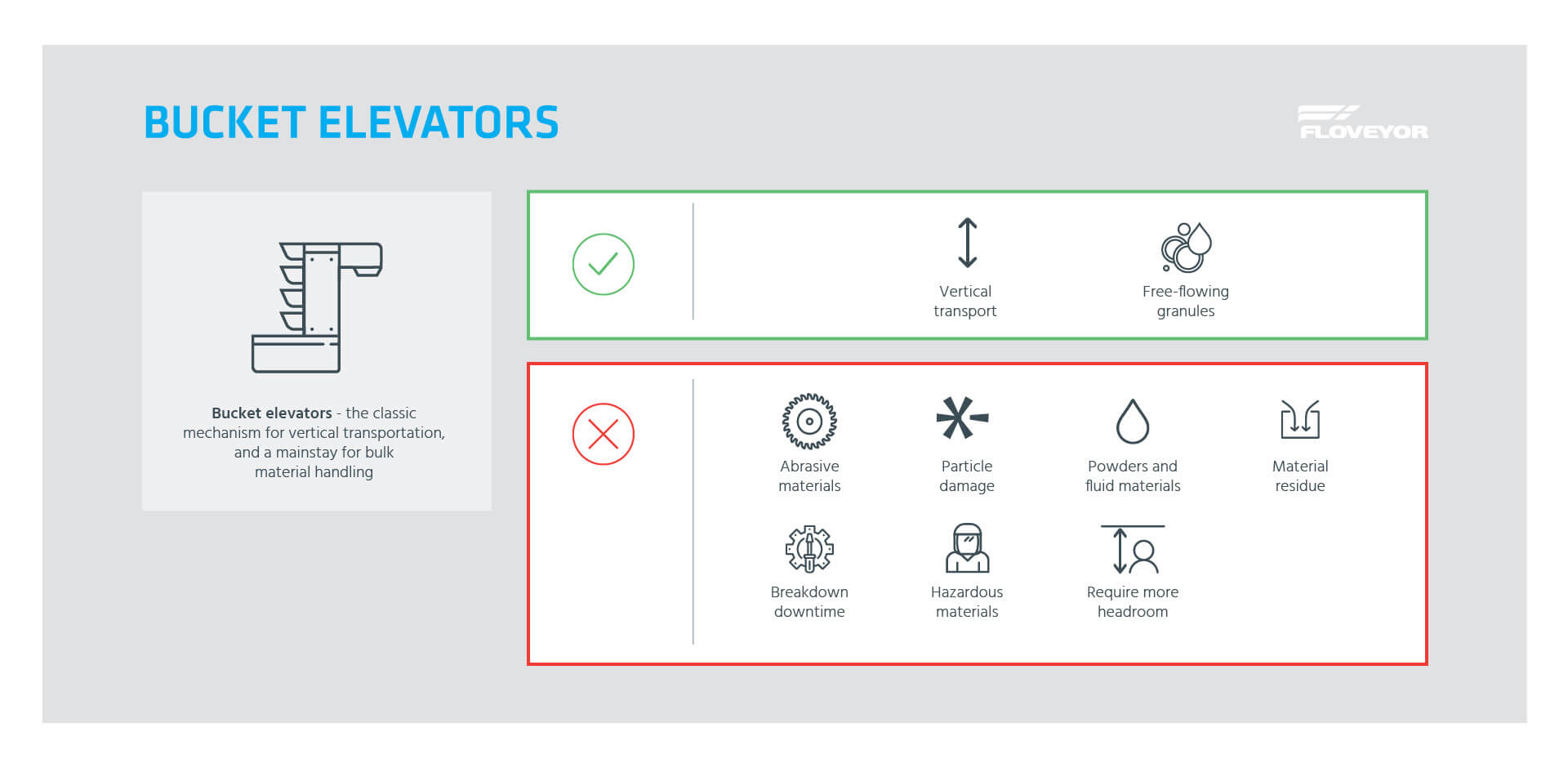

4.6 Bucket Elevators

One of the classic mechanisms for vertical transportation, a bucket elevator has been a mainstay for bulk material handling.

Best for:

- Vertical transport: Bucket elevators are optimised for moving materials upwards, making them a go-to solution for elevating bulk materials over long vertical distances.

- Free-flowing granules: Owing to the design where materials are fed directly into the buckets, these elevators perform exceptionally well with granular materials that have good flow characteristics. This ensures efficient filling and emptying of the buckets.

Concerns:

- Wear with abrasive materials: When abrasive materials come in contact with the elevator’s chain, sprocket, or pulley mechanisms, there i‘s a heightened risk of wear. Regular inspections and maintenance become essential to avoid unplanned downtimes.

- Potential for particle damage: As the materials are scooped up and dropped at discharge points, there’s potential for fragile particles to get damaged, which may not be ideal for certain applications.

- Limitations with powders or highly fluid materials: Powdery or extremely fluid materials may not settle well in the buckets, leading to inefficiencies or spillage. They may also cause challenges with bucket filling and discharging.

- Material residue concerns: Residues, particularly from sticky or wet materials, can accumulate in the buckets or along the conveyor path. Over time, this might lead to operational inefficiencies and require periodic cleaning.

- Downtime in breakdowns: A malfunction or breakdown can lead to significant downtime, especially given the vertical nature of these systems. Restoring operations can be time-consuming, particularly if the issue is deep within the elevator’s structure.

- Hazardous material handling: Due to potential challenges in sealing, larger internal volumes, and possible spillages, bucket elevators might not be the most suitable choice for handling hazardous materials. There i’s an amplified risk of material exposure, both to operators and the environment.

- Require more headroom: Bucket elevators typically require straight-line installations, either vertical or horizontal. This often necessitates the need for additional height to accommodate gravity chutes for horizontal distribution post-elevation. As a result, there can be increased costs associated with engineering and infrastructural support.

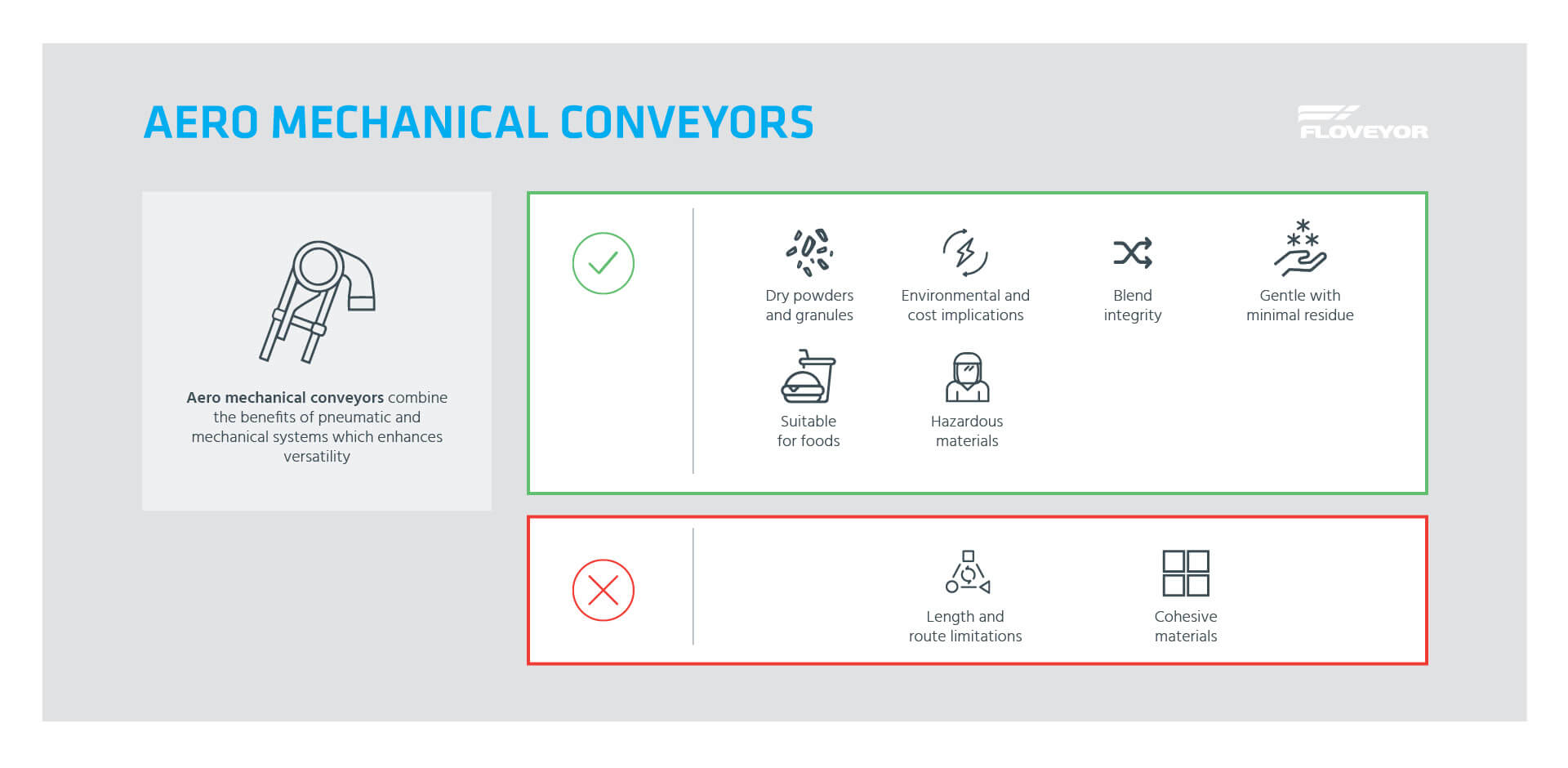

4.7 Aero Mechanical Conveyors

Harnessing the power of both air and mechanical forces, an aero mechanical conveyor (AMC) offers unique advantages in the bulk material handling sector. Their design combines the benefits of pneumatic and mechanical systems which enhances versatility.

Best for:

- Dry powders and granules: AMCs excel when moving dry powders and granules, especially those up to around 12mm in size. Their combination of airflow and mechanical movement ensures a smooth transfer.

- Efficient elevation with low environmental impact: AMCs are notably efficient when transferring materials vertically. They use considerably less energy than many alternatives and contribute to ESG maturity in a plant.

- Blend integrity: AMCs maintain the integrity of blended products, ensuring that mixtures remain consistent throughout the transport process.

- Gentle conveyance and minimal residue: Materials are treated gently, reducing the risk of damage. The AMC design typically results in near-total batch transfers with negligible residue, ensuring maximum material delivery.

- Suitability for foods and hazardous materials: AMCs are an excellent choice for transporting foods or hazardous materials due to their sealed and efficient system which reduces or eliminates contamination risks.

Concerns:

- Length and route limitations: AMCs have length constraints and typically require direct, line-of-sight routes, which can limit their applicability in more complex systems.

- Cohesive or agglomerating material challenges: Materials that tend to stick together or form lumps can present challenges for AMCs, potentially causing blockages or inefficiencies.

4.8 Flexible Augers

The flexible auger, or flexible auger conveyor, is often seen as the versatile cousin of traditional screw conveyors and is prized for adaptability. They use flexible Archimedes screws to achieve complex installation routes.

Best for:

- Fine to medium granules: Their design lends itself to handling materials ranging from fine powders to medium-sized granules, especially if they aren’t abrasive.

Concerns:

- Cohesive material handling: Cohesive materials can pose challenges, leading to potential clogging or inconsistent movement through the auger.

- Potential particle damage: The screw mechanism, especially when handling delicate materials, can introduce the risk of particle damage or degradation.

- Residual material: Flexible augers, given their design, might leave behind a large amount of residue compared to other conveying systems, leading to potential material losses.

- Blend separation: Blended materials may face the risk of separation due to the screw movement, leading to inconsistent material delivery.

- Heavy density material limitations: These augers might struggle with heavier or denser materials, as the flexible screw mechanism might not provide the necessary force for efficient transport.

5. Special considerations in food handling

Handling food products comes with its own set of unique challenges and requirements. When considering a conveyor system for food applications, there are several factors to bear in mind to ensure the safety, quality, and efficiency of the process.

Download: Conveyor System Comparison poster

5.1 Material quality

Ensuring the quality of food materials during transport is paramount.

No contamination

The conveyor system must be designed to prevent any form of contamination. This includes ensuring no foreign materials or debris comes in contact with the food, and there’s no cross-contamination between different food batches.

Particle integrity

Maintaining the structure and quality of the food particles is essential. The system should ensure gentle handling to prevent damage or changes to the food’s texture or form.

5.2 Cleaning and sterilisation

Given the sensitivity of food products, cleanliness cannot be overstated.

Easy cleaning

Conveyor systems used in food applications should be easy to clean. This includes having components that can be easily accessed, disassembled, and reassembled after cleaning.

Preventing cross-contamination

Regular sterilisation can help prevent bacterial growth and cross-contamination between batches, especially when switching between different food products.

5.3 Compliance and regulations

Adhering to industry regulations is not just about following the law – it’s about ensuring consumer safety.

Meeting food safety standards

Conveyor systems for food handling must meet stringent safety standards. This includes ensuring materials used are food grade and the design prevents contamination risks.

Read more: Download a selection guide for food and beverage conveying systems.

6. Challenges and solutions

Even the best systems can face challenges. Being prepared and having solutions at the ready can make all the difference in maintaining efficiency and product quality.

6.1 Residue of materials

Leftover material in the system can lead to inefficiencies and potential contamination. Wastage reduces yield and lowers your ROI. Time spent cleaning between batches can lead to increased production costs. Look for a bulk materials conveying system that provides total batch transfers.

Systems ensuring complete material evacuation

Incorporate mechanisms that ensure total evacuation of materials, like vibratory systems or blow-through designs, to ensure minimal residue is left behind.

6.2 Damage of particles

The structural integrity of materials, especially food, can be vital to the end product’s quality.

Minimise breakage

Opt for systems that ensure gentle handling. For instance, pneumatic systems using dense phase conveying can reduce the force exerted on particles, minimising breakage.

6.3 Segregation in blends

Uniformity is key, especially with mixed materials.

Maintaining uniformity

Design the system to minimise disturbances that can lead to segregation. Employing consistent speeds, gentle handling, and other measures can help maintain blend uniformity.

7. Collaborating with conveyor manufacturers

Selecting the ideal conveyor system for specific bulk material handling requirements is not a decision to be taken lightly. Collaborating closely with conveyor manufacturers can simplify the selection process and ensure a system that meets operational demands.

7.1 Role of expertise

Leveraging manufacturer knowledge

Manufacturers possess intimate knowledge of their systems, their capacities, and their limitations. They’ve often seen a multitude of applications and can provide insight into which systems have been most successful under similar conditions. By openly discussing requirements and constraints, you can capitalise on this expertise to narrow down the best choices. The conveying system manufacturer can perform materials testing to ensure the proposed system operates as expected.

7.2 Custom conveyor system

There are instances where generic, off-the-shelf conveyor systems might not align perfectly with unique operational demands.

When off-the-shelf doesn’t fit

In situations where standardised solutions fall short, manufacturers can tailor their systems or offer custom-designed solutions. These bespoke systems are crafted to fit specific requirements, ensuring optimised performance and longevity. Such customisations, while possibly demanding a higher initial investment, can offer significant long-term value in terms of efficiency, reduced downtime, and maintenance savings.

Conclusion

The complexities associated with dry powder and granule conveying, especially when considering specific material characteristics and operational requirements, underline the importance of a meticulously chosen conveyor system. It’s not merely about moving materials from point A to B, but doing so efficiently, safely, and without compromising the quality of the product.

Selecting the right conveyor system demands a deep understanding of material properties, operational needs, and the intricacies of different conveyor technologies. It is a decision with long-term implications on operational efficiency, safety, and bottom-line results.

Always prioritise thorough assessment, take the time to consult with experts, and when in doubt, lean on the vast experience of conveyor manufacturers. The success of any bulk material handling operation for powder and granules hinges on these foundational choices. Make them wisely.

Find out more about Floveyor’s conveyor systems for better powder handling

If you’re considering conveyor systems for your next bulk materials powder handling project, get in touch with Floveyor.

We invented aero-mechanical conveying in 1958 and continue to evolve powder handling conveyors and process line technology. We can help you determine the best conveyor for your plant and perform materials testing to ensure your performance expectations are being met.